| Home | Open Account | Help | 190 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Steam & Excursion > Monthly Inspections & Out-Of-Service Months Are Vital Records!Date: 10/23/16 04:22 Monthly Inspections & Out-Of-Service Months Are Vital Records! Author: LoggerHogger One of the many aspects that was part of everyday life during the steam era was the mandated monthly inspections of steam motive power. That continues on today for those steam engines lucky enough to be still in service.

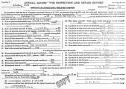

Up until the creation of the current 1472-day inspection rules that we now operate under, one of the most important aspects of this inspection routine was the recording of the "out-of-service" months for a given engine. This was done to extend the overall time between the re-tubing of boilers. Back in the days of steam the boilers could go 5 years between re-tubing. This was 5 years of service. The rules back then allowed any month that the engine was NOT in service to be recorded and that month would NOT count against the 5-year re-tubing cycle. The common practice was to record those out--f-service months on the back of the monthly inspection certificate as we see here with Pacific Lumber Company's 2-6-2 #29. These records can now be a valuable source of information as to when a particular steam locomotive operated during it's life. The photo of #29 was taken by W. Sievers in 1938 as TPL #29 backed a train of loaded log cars past the mill buildings in Scotia, California towards the waiting log pond. Such were the records of operating steam locomotives "back in the day". Martin Edited 4 time(s). Last edit at 10/23/16 04:32 by LoggerHogger.    Date: 10/23/16 07:55 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: elueck These records are valuable to historians in other ways as well. They were usually done at the time of the monthly boiler wash and often include a copy of the boiler wash record as well.

They were only required when the locomotive was operating in ICC service but not when it was operating in industrial service. A logging engine in the woods strictly operating on that trackage and not on any common carrier main line was not subject to those rules although good operating practice would require a monthly boiler wash for them as well. For engines in non ICC service, often the only records that may be available are those of the annual state boiler inspections. This provides us with another opportunity to look at operations where only the paper records survive. From these records, for logging lines for instance, we can deduce not only when engine wWeas in service, but what sort of service that it was performing. I have seen notes on the monthly reports that tell you that a locomotive that has been in ICC service, is no longer in that service, being leased to the parent lumber company or another lumber compay for instance. By the same token, a locomotive long on the roster, suddenly shows up as being in ICC service might mean that it has gone from working in the woods, to working on the ICC main line. Sometimes the locomotive from another railroad shows up in the inspection records meaning that it was probably leased to the inspecting carrier also. Access to enough of these records can give a historian a very interesting picture of short line or logging railroad operations. Date: 10/23/16 08:28 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: Earlk The old ICC/FRA rule was 48 calendar months of service after refluing. There was no provision for out of service time in the initial 48 months. However, if the locomotive was out of service for anytime during that 48 months, the flue time could be extended by the out of service months up to 60 months (five years). After the five calendar years, one had to apply to flue time extensions, which were granted on a yearly basis.

When I worked for the Cumbres & Toltec, we would reflue a locomotive and put it in service. Because we essentially only operated the locomotive for six months of the year, we would get all our out of service months added to the 48 months (not to exceed 60 months). So, we would get 5 years before needing to apply for a flue extension. To apply for a flue extension, you sent a letter to the FRA, with an "appropriate bribe". That is what we called the token fee required to file for an extension. I think it was $5 or something like that. Then you'd open up the front end, remove the petticoat, screen, nozzle etc. and pull the bottom 2 flues of the boiler. If you wanted to be on good terms with the inspector, you'd thoroughly clean the smokebox and firebox. When the inspector showed up, he'd look things over, see how much scale had accumulated it the boiler barrel, and hopefully give you a one year extension. Usually the inspector would give you a heads up if he thought you were getting near the end of the road for extensions. We ran lots of years on extensions. 484 was flued by the Rio Grande in 1965. It ran until 1968 for the Rio Grande, and operated for the C&TS from 1971 to the end of 1981 on flue extensions. In reality it was 484's bad driver tires that parked her at the end of 1981. 487 was flued by the C&TS in 1973 and ran until late 1980's (which was about 15 years - the current limit). Date: 10/23/16 09:02 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: wcamp1472 What to be very suspicious about.....

In "small" operations it was common for one person to sign-off on three signatures lines. It is commendable that the signatures on this sample are clear and readable. Illegible signatures are VERY suspect. If the signatures are all alike and unreadable ---- RUN, don't walk away from that boiler... To me, in today's post-Gettysburg boiler explosion environment, having the same person sign these 3 blocks is a 'red flag' about the integrity of the work attested to. Especially when the supposed supervisor attests to his own signatures..... I prefer to see 3 individuals names listed, with the third signature representing a competent supervisory person. Its just too easy to falseify the document, and to not ctually perform the work of cleaning out the water glass spindles and other cleaning necessities. Its especially troubling if the files are filled with similar inspection records, all with the 'same names'. You really should be able to have confidence that the safry devices are cleaned and faithfully maintained. Such forcing of paperwork can lead to disastrous outcomes. Thanks for posting. The example posted is very instructional---- as to what makes a suspicious inspection record. W. Date: 10/23/16 09:40 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: callum_out If the inspector from the insurance carrier is worth a damn you won't get it by him.

Out Date: 10/23/16 10:15 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: px320 Good topic.

When Short Line Enterprises purchased the 20th Century Fox collection in 1972 it included Dardanelle & russellville 4-4-0 No. 8 (Cooke L&M 1888). Fox provided their copies of all of the locomotive records they received drom the D&R when they purchased the engine in 1945. It had been rebuilt to operable condition in 1938 for use in the Fox movie "Jesse James." Following completion of filming the D&R used the engine in regular service until the flue time and extensions ran out. Here is a copy of the Annual report from October 1943 with the out of service times and flue extension info on the back. They sold the engine to Fox after the extension tome ran out. Edited 1 time(s). Last edit at 10/23/16 17:49 by px320.   Date: 10/23/16 10:33 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: LoggerHogger Neat history there Stan. Thanks for posting.

Martin Date: 10/23/16 16:38 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: wcamp1472 Again, it's very suspicious where "F.R. Hanna" signs-off on all the attestation blanks, as both the worker that performed the work and the supervisor attesting to that work.

Apparently, Very common back in the day..... In today's world that can be very questionable, and today's forms have no notary requirement ( not legally meaningful, anymore). Yes, the old forms procedures came in the era of strong unions, heiarchical Managements and lots of workers surrounding the engines at boiler washout time, etc. L In today's environment, it's common that smaller crews surround the engines, and we're totally left to TRUST that the safety appliances, that are most subject to sediment clogging are, in fact cleaned and reamed ----- to keep their passages free and clear. The small pipes leading to the waterglasses are vital to keep open, you can only ream those pipes of the solid build up of encrustations during the time when the boiler is drained. Sediment build up in passages where water flow-rate is is low, & where accumulations tend to build up rapidly, once started. the water glasses and water columns are rarely blown out, compared the the number of hours that the boiler is under steam. How long does it take to do the tests? 30 to 40 seconds? Out of 30 days of steaminhg, that's not much time to keep those pipes cleaned-out. Unlike public displays of boiler blow-downs ( vital), these maintenance steps are hard to independently verify. I tend to not trust forms where ALL of the signature blocks have the same name.....that can be very scary, without some way to get confidence that the signatures are the last step of conscientious, diligent performance of the physical cleaning of the vital piping involved with the water glasses. Washouts aren't so much about the hosing-out of the boiler, as they are about the maintenance of the cab safety equipment and things like water glasses, injectors, globe valves, etc... So, as LarryDoyle has demonstrated, daily waterglass testing is vital. And one of the observations to make is how rapidly the water level responds, in the glass,. Does the level recover immediately, or does the water level act sluggish and slowly? You want rapid action, you want to see evidence of tool marks on the valve bonnets and nice, clean glasses and glass safety guards. If stuff hasn't been taken apart, and yet the dates on the forms are fresh ---- something ain't right.... W. Edited 1 time(s). Last edit at 10/23/16 17:43 by wcamp1472. Date: 10/24/16 04:33 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: PlyWoody Has anyone ever found old paper records in the archives of the State covering boiler inspection of steam locomotives or of the sawmill boilers of logging railroad? I have tried all department of Vermont and was unsuccessful. Then I discovered that when Hartford Steam Boiler Inspection and Insurance company moved to a new headquarters in Hartford, they totally destroyed all those old records which covered most of the USA. It would be great if any records are in Denver of boiler inspection record of logging railroad, covering such lines like Rio Grande & Pagosa Spring, The Pagosa Lumber Co. The Trinchera Estates Co. The Montezuma Lumber Co.,. A. A. Rust. The New Mexico Lumber Co., Boston Coal & Fuel Co. La. Plata Coal Co., Middle Park Lumber Co., Uintah Ry, and a few others. The record may be in safety or general wellfare if there are such departments. Most states looked to the ICC and Hartford to do the inspection, and did not even check private line boilers.

Edited 1 time(s). Last edit at 10/24/16 04:36 by PlyWoody. Date: 10/24/16 09:01 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: px320 When Bill Oden and I purchased Rogue River Valley Railway No. 1 from Chad O'Connor in March of 1967 it was on his private spur and a leased portion of the Santa Fe's Cucamonga Foothill Spur in Alta Loma, CA.

As such it was covered by State of California boiler regulations and inspected annually by Hartford. The inspector would come out, look at the boiler and firebox (we removed the dome lid for inspection) and in a week or so we would get a new insurance certificate. There was no other paperwork filled out or sent in. Photo taken summer of 1967  Date: 10/24/16 13:24 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: Realist Let's get something straight about boiler washes. The rule never said you could go 30 days without washing the boiler. It said you could not go MORE than 30 days without washing the boiler.

You could wash it out every few days if you wanted or needed to. In fact, a lot of western and southwestern railroads with problem water supplies washed boilers every week or even more often, determined by the tests of boiler water samples taken on arrival at the roundhouse every trip. Today, you are not allowed to go more than 31 service days, and a few wise guys have figured out how to stretch those 31 service days over several calendar months, avoiding washing their boilers for as long as possible. That may be legal, but it's not very smart, and will eventually bite them in the fanny. Then there are one or two who have a very liberal personal definition of a service day, usually in an attempt to go more than 31 actual service days. Like maybe 34 or 36, for their personal convenience. Date: 10/24/16 16:37 Re: Monthly Inspections & Out-Of-Service Months Are Vital Records Author: wcamp1472 Realist...

My point about the relative importance of flushing out the boiler, versus doing the reaming of the water glass tubes and scraping of the arch tubes, etc. is that the flushing is not nearly as important as the cleaned-out waterglasses and related piping. So yes, flushing the boiler is beneficial and can be repeated as often as desired. My point is that the CRITICAL aspect of the proper reaming of the water glass piping, the water column supply pipe , as well as the supply pipes to low water alarm devices. Encrustation of those supply pipes, valves, tubing etc. is a characteristic of all boilers, fed by raw water and treated in the boiler ( as opposed to stationary boiler practice) ----- the only way to ensure that these critical components are scraped clean is by minute visual examination. Please stress these IMPORTANT steps to be performed over the hosing-out of the boiler interior. Sticking a hose nozzle into the washout plug holes does little other than to rinse-off the scale encrusted tubes and firebox sheets. Too often the rinse and repeat cycle is faithfully followed while the critical part of the operation is omitted, glossed-over or only partially completed. Typically, boiler flushes performed more frequently than the "30-day interval", do NOT normally include the additional effort of the reaming of the associated water glasses, etc. Newbies can possibly confuse the hose-out of the boiler with critical work of the attention paid to the safety devices. Thanks for your attention. W. - |