| Home | Open Account | Help | 370 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Steam & Excursion > Steam Engine Reverse Lever: What Does It Do?Date: 04/10/19 22:00 Steam Engine Reverse Lever: What Does It Do? Author: RailRat Iv'e read about that Reverse lever a lot lately here on TO, but have no clue what it does, It's being used in notches by the engineer as the locomotive is moving forward, can anyone explain please? Thanks in Advance

Jim Baker Riverside, CA Date: 04/11/19 02:24 Re: Steam Engine Reverse Lever: What Does It Do? Author: wcamp1472 Good question ....

It does two things: Determines the direction that the loco moves, when it first starts & it allows for variable steam admission periods —- power regulation, once underway. Remember, that a locomotive piston, alternately, receives steam on either side of its two ’faces’, according to its rotative position in the power stroke. There are two major events in the power cycle ( on ONE SIDE) of each piston: Power & Exhaust. 1 power stroke occurs over 180deg of rotation, bottom half of driver, the 2nd power stroke of the rotation occurs through 180 deg, over the top half of driver rotation. With a piston at either the front or rear cylinder heads is said to be on “Dead-center” when any driver rotation pulls the piston away from the adjacent cylinder head.. Obviously, part of the power stroke is the admission portion—- gets the steam into the cylinder, and once expanded, the used steam must be exhausted ... The 4 events are ‘timed’ by the spool valve that regulates the 4 steam events in each ( of the two) power strokes that a driver makes in one revolution.... Again, there are two drivers on each axle,so in one revolution, there are 4 power stroke events—- two for each side. There is a shuttle valve, driven by the rotation of the drivers, that controls the steam into one of the two ports at each end if the cylinder. For steam admission, the spool,valve pressurizes the port leading to the piston. Fir exhaust, the spool valve must be moved to direct the used steam up the stack.... that’s the origin of each ‘chug’... So, the valve, driven by the rotating wheels, admits steam at the beginning of each power stroke, and exhaust it he used steam up the stack....thus controlling the pressure in the steam ports and the cylinders. As the wheel rotates, steam from th boiler pushes the piston all the distance of the power stroke. However, Steam, being an expanding gas exerts pressure, even when the admission valve is closed, and no more steam is supplied by the boiler. The trapped steam in the cylinder continues to push the piston all the way u til the exhaust valve opens... CHUG! Desigmers, a long time ago, realized that the expansive power of the trapped steam was entirely dependent on the steams temperature....The higher the temperature, the greater the pressure.... also, if heated very hot a little bit of steam can power the whole stroke... So... designers realized that they could change the admission periods of the power stroke, by varying the point of the stroke when the admissionport closes, trapping the hot gas in the cylinders.. Variabke admission. The engineer has a lever, eaither a long, manually operated lever, or a short power-assisted lever. In its central position, ( straight up, it centers the valve.... to start, the engineer places the reverse lever all the way forward...this opens the admission port to the boiler pressure ... the steam from the boiler is controlled by the throttle...The on/off valve from the boiler. The throttle opening is adjustable to allow for controlled starts, thus allowing more steam to flow as speed increases. Once under way, the engineer, by adjusting the the reverse lever, now shortens the live-steam power stoke and use the heat expanding steam to expansively continue to power the piston until the exhaust portion of the stroke releases the steam up the stack. Remember, on each (two cylinder) engine there are 4 power strokes for each driver revolution. And by adjusting the admission length of each stroke, the engineer can use the power of heat to move the train, and NOT rely solely on the pressure from the boiler.. The British refer to the 4 stroke-events as: Suck,Squish, Bang, Blow. ( admission, compression, expansion[BANG], exhaust).. Now, that’s the basics...dig further, now that you know the 4 valve events.. Wes Camp (not proofed , yet..) Edited 2 time(s). Last edit at 04/11/19 08:09 by wcamp1472. Date: 04/11/19 11:25 Re: Steam Engine Reverse Lever: What Does It Do? Author: wcamp1472 A little more clarity about the ‘notches’...

The term notches refers to the position locking mechanism of the direction lever.... if not locked into a position other than neutral, the lever can become a puppet of the valve gear. And could be slapped back and forth as the drivers rotate. As locos developed in the 19th century ( late 1800) they became improved in boiler pressure and weight, and pulled heavier trains... The early steam distribution valves of the era were held onto to the smooth port-plate, and slid back and forth by the valve gear, driven by the rotating axle.. The porting of the cylinders, arranged for the slide valve to alternatively open the ports at the outer edges of the square valve... aka the ‘outside’ admission valves. Exhaust passages, connected the exhaust passage of the valve to the exhaust passages leaving to the base of the smokestack. There is a central, hollow recess in the bottom of the shuttling valve, that is in constant communication with the exhaust passages. That arrangement leads to immense pressure differential... With the throttle open, steam pressure forces the slide valve tighter onto the flat, slide valve seat. Since the exhaust cavity is open to the atmosphere, 150 lbs of BP gets multiplied by the number of square inches in the total area of the sliding valve, commonly called a D valve, being arched, with a flat side rubbing on the valve port-plate... With the axle cam(s) driving the valve rod to and fro, there is tremendous rubbing friction. Remember that we said that the engineer can adjust the travel, and shorten the portion of the stroke that receives the full boiler pressure, thus making use of the trapped pressure in the cyjdinders to exert force all the way to the end of the stroke. The engineer controls the sliding link-block. The link is a crescent-shaped, rocking lever, that on some valve gears ( in between the frames) is suspended by a system of levers, it controls the length of travel of the D valve, in the steam chest over the driving pistons... The cams that swing the suspended link are very strong, and force the D valve to slide, thus opening and closing the ports... The lever that operates the crescent-shaped rocking link, is the large “Johnson Bar” in the cab, typically in front if the engineer... To lock the Bar at various points along the locking-quadrant, square notches are machined into “quadrant”, at the center and about 7 or 8 either end of the circular-arc that makes up a guiding and locking ‘quadrant’... When the engineer is ‘working steam into the cylinders ( of slide-valve equipped) locos, great forces are at work forcing the D valve to move on its seat, but the pressure on its back makes the D valve behave like a brake shoe... if the engineer releases the Johnson Bar latch from its place in the quadrant, he risks being thrown back and forth with great rapidity, and being thrown around in the cab.. The valve gear’s lifting link and Johnson Bar are now thrashing around with the D-valve, now the fulcrum, held solidly in-place by the boiler pressure ... It was common for old-time engineers to never risk that eventuality, and they ran entire trips with the Johnson Bar, all the way forward ( or reverse). By the 1890s, big 2-8-0s and big passenger engines were becoming very balky and dangerous to operate... While rolling, Engineers resorted to closing the throttle, thus dropping the valve chest pressure which was forcing the slide valve onto its seat, before un-latching the Johnson Bar and moving to a shorter valve travel... as speeds picked-up. Climbing a grade with a freight train, made closing the throttle an impossibility —- ‘cause the train might stall!!! So, they fought soakers every foot of the way up those endless grades —- Engines were all hand fired... So -called “Balanced” slide valves were introduced, in an effort to reduce the total area of the valve subjected to boiler steam pressures... There were several variations of balanced valves, variants being dictated to avoid patent infringements... With the arrival of successful superheating of cylinder steam, a cure for the risks of Johnson bars and slide valves was immediately in need of a cure... More to come, sometime .. W. To be proofed, yet.. Posted from iPhone Edited 2 time(s). Last edit at 04/11/19 13:54 by wcamp1472. Date: 04/11/19 13:16 Re: Steam Engine Reverse Lever: What Does It Do? Author: LarryDoyle The reversing lever on a steam locomotive, as Wes says, sets the timing of the admission and exhaust of steam in the

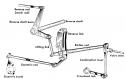

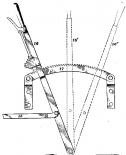

cylinders of a steam locomotive. Sort of like the timing and advance of an auto engine. Placing the lever in the center position of its quadrant there is virtually no movement of the valves controlling steam/exhaust , so no power is delivered (OK, Purists, forget about lead for now). Placing the lever ahead of center times the valves for forward motion, and back of center for backup movement. Starting a train, the engineer places his reverse lever in the full forward position, opens the throttle slightly to admit steam to the cylinders, and releases his brakes. The engine starts moving forward, with steam admitted to the cylinders for nearly the full stroke of the piston for maximum slow speed starting power. As speed and throttle increase there becomes less time for the exhaust ports of the valves to do their job, and the "back pressure" increases limiting the speed of the engine. The engineer then "hooks up" the valve gear, thereby opening the exhaust ports sooner and closing the steam admission ports sooner which allows the engine to breath more easily using less steam while relying on the tremendous expansive power of the steam in the cylinders, as Wes described. It becomes more efficient. The first diagram below illustrates the basic mechanism of a valve gear. What the reverse lever does is change and adjust the relationships of the points on the lever d-g-e. There were dozens of different valve gear designs on American railroads. Some were little used, even "one-offs". One of the most widely used in the 20th Century was the Walschaert valve gear shown in the second diagram, and it's about the easiest to understand. If this subject piques your interest you might want to download the Dockstader animations of locomotive valve gears. See this post from a year and a half ago for more about it and how to get the animations for your computer. https://www.trainorders.com/discussion/read.php?10,4416190,4416190#msg-4416190 Finally, here's a video clip of the Dockstader animation of Walschaert valve gear. -LD Edited 1 time(s). Last edit at 04/11/19 13:37 by LarryDoyle.  You must be a registered subscriber to watch videos. Join Today! Date: 04/11/19 14:14 Re: Steam Engine Reverse Lever: What Does It Do? Author: LarryDoyle This shows the old style "Armstrong" (or manually operated by a strong arm) lever used on engines up to about 1910. The lever is about 6 feet long with the top 4 feet sticking up out of the floor to the engineers left. The notches Wes referred to are evident.

After that, most new construction and many rebuilt engines had a power assisted reversers, operated by a similar handle and quadrant, but much smaller - a lever about 12 to 18 inches long, but still locked in place by notches in the quadrant. The clanking of the manual reverser in the quadrants notches with every rotation of the drivers was one of the sounds the engineer came to know and love. -LD  Date: 04/11/19 14:28 Re: Steam Engine Reverse Lever: What Does It Do? Author: wcamp1472 Clanking!!!

THAT scares me...!!! i don’t think I’d have the courage to open the latch with it CLANKING.. Wes Camp Date: 04/11/19 14:58 Re: Steam Engine Reverse Lever: What Does It Do? Author: LarryDoyle Wes wrote, in part:

--- The lever that operates the crescent-shaped rocking link, is the large “Johnson Bar” in the cab, typically in front if the engineer... To lock the Bar at various points along the locking-quadrant, square notches are machined into “quadrant”, at the center and about 7 or 8 either end of the circular-arc that makes up a guiding and locking ‘quadrant’... When the engineer is ‘working steam into the cylinders ( of slide-valve equipped) locos, great forces are at work forcing the D valve to move on its seat, but the pressure on its back makes the D valve behave like a brake shoe... if the engineer releases the Johnson Bar latch from its place in the quadrant, he risks being thrown back and forth with great rapidity, and being thrown around in the cab.. The valve gear’s lifting link and Johnson Bar are now thrashing around with the D-valve, now the fulcrum, held solidly in-place by the boiler pressure ... It was common for old-time engineers to never risk that eventuality, and they ran entire trips with the Johnson Bar, all the way forward ( or reverse). By the 1890s, big 2-8-0s and big passenger engines were becoming very balky and dangerous to operate... While rolling, Engineers resorted to closing the throttle, thus dropping the valve chest pressure which was forcing the slide valve onto its seat, before un-latching the Johnson Bar and moving to a shorter valve travel... as speeds picked-up. Climbing a grade with a freight train, made closing the throttle an impossibility —- ‘cause the train might stall!!! So, they fought soakers every foot of the way up those endless grades —- Engines were all hand fired... So -called “Balanced” slide valves were introduced, in an effort to reduce the total area of the valve subjected to boiler steam pressures... There were several variations of balanced valves, variants being dictated to avoid patent infringements. --- My solution to that problem on NP 328 was to treat the reverse bar as a 400 lb. dance partner, and not let her take the lead. Just reaching over and gently releasing the latch could easily get you some bruises, and maybe a broken arm. I am not making this up. Instead,, embrace that bar. Treat it like you were hugging it, so the entire mass of your body becomes one with the bar, and it can't hit you or throw you. Plant a foot on the quadrant at where you want to reposition it. Gently squeeze off the latch and let it glide to your left or right by leaning slightly. When you feel it touch your boot release the latch. YOU'RE running the engine. Don't let the engine run you. -LD P.S. Generally, slide valve "soakers" are pussycats to fire and handle compared to later power. But if she's gonna bite ya - this is where it will happen. Date: 04/11/19 15:03 Re: Steam Engine Reverse Lever: What Does It Do? Author: LarryDoyle wcamp1472 Wrote:

------------------------------------------------------- > Clanking!!! > THAT scares me...!!! > > i don’t think I’d have the courage to open the > latch with it CLANKING.. > > Wes Camp Well, you have to recognize good clanks from bad clanks. -LD Date: 04/11/19 15:57 Re: Steam Engine Reverse Lever: What Does It Do? Author: elueck All of this is why some railroads overseas and in Canada, along with some in the USA embraced the screw type power reverse controller in the cab. I remember the first time that I got in the cab of NKP 639 at the park in Bloomington, IL and was training to be a sunday docent, and went looking for the "johnson bar" about which I had heard much, only to be confronted by the screw type power reverse controller.....

Date: 04/11/19 17:35 Re: Steam Engine Reverse Lever: What Does It Do? Author: Defective_Detector And oddly enough there are reports that even with the screw reverse, some engineers ended up breaking their fingers and hands because the screw would suddenly turn,

Date: 04/11/19 18:19 Re: Steam Engine Reverse Lever: What Does It Do? Author: RailRat Thanks wcamp1472 and Larry Doyle (the computer animation really helps). Lots of good info here to absorb, will be re-reading this till my old brain puts it all together! Hope it helps other folks understand too, especially the young interested ones out there.

Jim Baker Riverside, CA Edited 2 time(s). Last edit at 04/11/19 18:24 by RailRat. Date: 04/11/19 19:14 Re: Steam Engine Reverse Lever: What Does It Do? Author: zoohogger Great information. Another question.

When the drivers start slipping, you close the throttle(stop the slip) get the throttle back about where it was, maybe sand. Is there any advantage to adjusting the reverser one way or the other to prevent the next slip? Rick Z Date: 04/12/19 07:06 Re: Steam Engine Reverse Lever: What Does It Do? Author: LarryDoyle zoohogger Wrote:

------------------------------------------------------- > Great information. Another question. > > When the drivers start slipping, you close the > throttle(stop the slip) get the throttle back > about where it was, maybe sand. Is there any > advantage to adjusting the reverser one way or the > other to prevent the next slip? > > Rick Z Not really, in most cases controling the steam supply with the throttle should suffice. -LD Date: 04/12/19 08:33 Re: Steam Engine Reverse Lever: What Does It Do? Author: elueck Just found this on the Narrow Gauge forum. NZGR class K on a 2014 excursion. Beginning at about 4;55 there is a series in the cab of the engineer making a beautiful passenger start, using both the throttle and the reverse lever. As he starts out and gains speed, you can see him using mostly the throttle, with the reverse lever in forward motion. As he gains speed, he continues to open the throttle and move the reverse gear toward center. With further increases in speed, the throttle is mostly open, and he continues to move the reverse gear toward center to control the admission of steam to the cylinders even as the locomotive continues to accelerate.

http://ngdiscussion.net/phorum/read.php?1,369465 Date: 04/12/19 15:28 Re: Steam Engine Reverse Lever: What Does It Do? Author: LarryDoyle zoohogger Wrote:

------------------------------------------------------- > Great information. Another question. > > When the drivers start slipping, you close the > throttle(stop the slip) get the throttle back > about where it was, maybe sand. [snip] > > Rick Z If you throw on the sand, be confident that there is, indeed, enough sand in the sandbox. Part of your daily pre-trip inspection. If sand is applied to only one side of the engine during wheel slip conditions you can actually twist the axles and drive the engine out of quarter! There is a well known engine on one of our frequently posted major major tourist railroads that has a decided limp. Evicence of a twinsted axle. -LD Date: 04/13/19 07:06 Re: Steam Engine Reverse Lever: What Does It Do? Author: Txhighballer LarryDoyle Wrote:

------------------------------------------------------- > zoohogger Wrote: > -------------------------------------------------- > ----- > > Great information. Another question. > > > > When the drivers start slipping, you close the > > throttle(stop the slip) get the throttle back > > about where it was, maybe sand. > > > > Rick Z > > If you throw on the sand, be confident that there > is, indeed, enough sand in the sandbox. Part of > your daily pre-trip inspection. If sand is > applied to only one side of the engine during > wheel slip conditions you can actually twist the > axles and drive the engine out of quarter! There > is a well known engine on one of our frequently > posted major major tourist railroads that has a > decided limp. Evicence of a twinsted axle. > > -LD I was taught to never apply sand during a wheelslip as that could snap a crankpin if the drivers suddenly caught. Close the throttle to a point where the slip is abated, then open back up to a point just before the drivers slipped. If she is pulling, then leave her there, then apply sand. Date: 04/13/19 07:39 Re: Steam Engine Reverse Lever: What Does It Do? Author: LarryDoyle Txhighballer Wrote:

> I was taught to never apply sand during a > wheelslip as that could snap a crankpin if the > drivers suddenly caught. Close the throttle to a > point where the slip is abated, then open back up > to a point just before the drivers slipped. If she > is pulling, then leave her there, then apply sand. That's better, yet. Date: 04/13/19 19:56 Re: Steam Engine Reverse Lever: What Does It Do? Author: MMD This is on the "Cass Bank" a 2% grade Eastbound on the Midland Line between Christchurch and Greymouth on the West Coast of the South Island of New Zealand., always a "Must" photo run by on fan trips.

Malcolm New Zealand. elueck Wrote: ------------------------------------------------------- > Just found this on the Narrow Gauge forum. NZGR > class K on a 2014 excursion. Beginning at about > 4;55 there is a series in the cab of the engineer > making a beautiful passenger start, using both the > throttle and the reverse lever. As he starts out > and gains speed, you can see him using mostly the > throttle, with the reverse lever in forward > motion. As he gains speed, he continues to open > the throttle and move the reverse gear toward > center. With further increases in speed, the > throttle is mostly open, and he continues to move > the reverse gear toward center to control the > admission of steam to the cylinders even as the > locomotive continues to accelerate. > > http://ngdiscussion.net/phorum/read.php?1,369465 > |