| Home | Open Account | Help | 294 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Steam & Excursion > Temperature of water in tender affect injector performance?Date: 01/15/20 14:38 Temperature of water in tender affect injector performance? Author: PlyWoody If water get low in the tender and warms up on a hot afternoon, would that cause the injector to not want to work without numerous tries to get it to take? For example D&RGW K-36.

Date: 01/15/20 15:00 Re: Temperature of water in tender affect injector performance? Author: callum_out Yup, you'd think an injector with a flooded inlet would pick right up, not so much. SP #18 had a fireman side unit with a mind

of it's own, believe the new cones solved the problem. Out Date: 01/15/20 15:21 Re: Temperature of water in tender affect injector performance? Author: HotWater Personally, I've never experienced that. For example, we got so low on water in the tender on 4449, that the cold water turbine pump would no longer pump water forward to the Worthington Feedwater heat exchanger tank, yet the Nathan non-lifting injector made one more input, before it quit do to lack of water.

We stopped opposite a fire hydrant, and took on some water. Fun times in the dark. Date: 01/15/20 15:49 Re: Temperature of water in tender affect injector performance? Author: tomstp Many decades ago in far west Texas during extremely hot weather had water heat up so much that injectors on several 2-10-2.'s were failing of the T&P. It was caused by the fact that one water tank was not normally used much and the water got hot. After some weeks of this that was discovered as the problem and the man servicing the water tanks was instructed to dump the tank daily until the heat wave ended . That put an end to the problem.

Edited 1 time(s). Last edit at 01/15/20 15:53 by tomstp. Date: 01/15/20 17:00 Re: Temperature of water in tender affect injector performance? Author: wcamp1472 Yes...

There are two classes of injectors: 'lifting' and 'non-lifting'. 'Lifting' injectors are mounted up in the cab, which may place them above the water level in the tender. 'Non-lifting' injectors are mounted below the bottom of the tender. ALL injectors draw water into the body to flood the body with fresh water. tyere are Venturi tubes specially designed to draw water into the body --- the 'lifting cones' and there are longer Venturi tubes designed to force the water through the closed 'boiler checks', and into the pressurized boiler. The high-pressure canes are called the 'forcing cones'. The forcing cones are the heart of the injector. It seems contradictory for the same pressure of the boiler forcing the water into the boiler at higher pressure --- in order to open the boiler check valve. The design of the Venturi cones shapes the steam column into a pencil-thin jet, whose shape simulates a straight stream...that straight-stream, if not confined by the injector body, would shoot half the length of a football field --- and still maintain that pencil shaped stream. It literally shoots a high velocity steam jet, about as big as your index finger into the water flooding the body. Such a jet can literally cut though steel very smoothly. It contains an immense amount of energy. Inside the injector body the cold water is propelled by the high-energy jet into the boiler feedwater pipe ending at the boiler check valve. The High energy jet imparts some of its energy into accelerating the whole pipe of water to speeds of a couple of hundred feet a second --- if unconfined. it is that mass ( weight) of warm water, moving very fast, that fights its way into the boiler, even against the high pressure inside the boiler. Both designs, lifting and non-lifting, draw the water into their bodies under a very strong vacuum. There's a problem though ---- lowering their pressure, also lowers it's boiling point. If you're trying to draw hot water into the body, by lowering the pressure in the injector body, the lowered pressure causes the water in the supply pipe to boil, turn into steam, in the injector body. The suction is lost, and the injector 'breaks' ---- meaning that the boiler steam pressurizes the body and steam blows it the overflow pipe. Only when cold water gets to the body, will the Venturi-jet be formed and force water into the boiler. Lifing injectors are very susceptible to 'breaking', if trying to lift hot water From the tender. Non-lifting injectors can more easily be 'flushed' of hot water, by simply opening the water supply valve and allowing the colder water to flood onto the ground ( out the overflow pipe) , until the water supply runs cold... Then you can attempt a re-start of the steam-jet to get the injector to function. The main advantage of the lifting injector is that once 'started', the water supply can be very precisely reduced, while still forcing water into,the boiler. The water supply can be regulated-down to do that & the injector doesn't have to.flood the boiler with water --- cooling everything down. The superior water feed-rate regulation of the lifting injector allows the crew to restrict the feed-rate when traveling over flat territory; then, when hills are attacked, and more steam is used, you can simply 'widen' the water valve to admit more and more water. Non-lifting injectors are much poorer at "water flow regulation".... However, they are much more reliable, over-all because of the ability to get cooled-down very rapidly, and then can 'recover' form 'hot water episodes' more quickly. With the development of steam-operated water pumps, very slow water feed rates were more easily achieved than through using injectors. Pumped water was very cold entering the boiler....whereas, injector-fed water is partially pre-heated. Cue the "feed water heaters"! Problem solved... by using the tremendous amount of heat in the steam exhausted out the stack... to preheat the water, bound for the boiler.. At some point we'll discuss "open vs. closed " feed water delivery systems... W. ( am additional point... ‘Lifting” injectors have an easy job if the attached tender’s cistern-top is fairly high... The high level of a full tender of water requires a low Vacuum influence to fill the body with cool water. Naturally, as the day progresses, the amount of vacuum needed to lift the water up to the level of the injector body, means greater susceptibility to lowering of the boiling point.... Warm water boils very easily when the surface pressure is reduced... So, old-timers rarely passed a water tank .... without taking more water... even to top-up the tank. On lines using track pans... scooping was made very easily... Filling the tank in 30 to 40 seconds... maybe less, in “modern times”...) (to be 'proofed', yet) Edited 4 time(s). Last edit at 01/16/20 08:05 by wcamp1472. Date: 01/15/20 17:08 Re: Temperature of water in tender affect injector performance? Author: Earlk Yes, absolutely. The Hancock HNL Non-lifting Inspirators on the D&RGW K-36's are very sensitive to warm/hot water. When I would come on duty the first thing I would do is put my hand on the side of the tender on the shady side to see if the water in the tender was cool. If it was warm or hot, I'd have the engine sent up to water tank where the tank hoses would be dropped, and a good half a tank of cold water could be added before heading out of town.

The issues would be not only hard starting of the injector, but the warm water would make the injector "fine down" and lose capacity. If we started having troubles with the injector keeping up, we would stop at Cresco Tank and add a few feet of cold water. That would usually clear up the problem. The Hancocks seem to be more sensitive to this than other injectors. The starting valves on the Hancocks had a flaw in that the main steam seat where the valve ram closed had a removable seat. Presumably for replacement when it wore out. The flaw was the seat screwed into the starting valve body. The sealing surface to the ram was a nice 3/8" wide. The seat where it sealed in the valve body was about 3/32" wide, easilly steam cut and very difficult to get to seal up. The result was unless you shut the steam to the starting valve off at the turret, or shut the turret itself off, You had steam popping back into the tender tank (Hancocks are a closed overflow injector). If the engine was sitting around for a few days, it would get a warm tank of water. The lifting Simplex injectors didn't like warm water either, but with an open overflow system, any steam leak simply went out on the ground out the over flow. Until one night in Antonito where the 497's right injector was blowing more steam than normal, so he closed the overflow valve. When I got there and got on the engine, the tender was HOT. Steam came out of the manhole. We drained about 1/2 the tank, filled it with cold water, and still had really warm water. I decided to be brave and head west. About 15 miles out of Antonito, the fireman's gun gave up and I couldn't the engineer's gun to prime with the hot water. We ended up packing ice from the concession car to cool the injector and feed pipe down to the point where the fireman's injector would prime up and run. I had my fireman run the injector all the way to the next tank, and not shut it off. When the water got too high, open the blow down. On the other hand, the Strasburg copies of Sellers Non-lifting injectors were very forgivable with water temperatures. We used them on the San Luis & Rio Grande #18. Then would run great, and keep up with a tank of warm water. Date: 01/16/20 06:21 Re: Temperature of water in tender affect injector performance? Author: BAB Intresting thought it was only in large scale models it occured in thanks for the info.

Date: 01/16/20 08:06 Re: Temperature of water in tender affect injector performance? Author: Dreamer It amazes me that the lifting injector is considered so sensitive to water temp and yet the Southern Pacific used a lot of lifting injectors on a lot of older powerAlmost every 2-6-0, 2-8-0 were equiped with them. I wonder what they knew then that e do not know now.

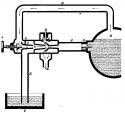

Dreamer Date: 01/16/20 08:26 Re: Temperature of water in tender affect injector performance? Author: LarryDoyle An injector is a marvelous device, as Wes said. The drawing below shows it's principle of operation. It takes steam from the boiler to suck water in from the tender, combine it with the steam and shoot it back into the boiler! The overflow at x dumps water on the ground for a few seconds when starting the injector until sufficient force can be developed to overcome the check valve at G to put water into the boiler. If the water in the supply pipe and hose at E is is too warm it will boil in the feed pipe and hose E and the injector will not be able to to generate enough force to open the check valve G.

The solution to that problem is to lock down the check valve at O and try starting the injector. Since both check valves G and O are closed, the steam will blow down pipe E back into the tender and clear it of warm water. Then, check valve O can be reopened and the injector should start to feed the boiler normally. I've never worked with a steam locomotive south the 45th parallel, so can't relate to and entire tender of water getting too hot to allow an injector to prime, just from heat from sunshine. It has to get hot enough to be uncomfortable to touch. Maybe it does happen in warmer climates. But, as Earl points out, a steam leak from the injector (intentional or accidental) into the supply pipe can blow enough steam back into the tender to warm it. At this time of the year it was actually necessary (It's -9 F outside as I write this) to prevent freezing of the supply pipe and tank. Also, any time of year, if the steam supply to the injector is not completely shut off when not using the injector, a trickle of hot water will condense and drain into pipe E filling it with hot water, making the pipe too hot to even put your hand on it. Simply blowing it back into the tender solves that problem. -LD  Date: 01/16/20 13:13 Re: Temperature of water in tender affect injector performance? Author: wcamp1472 Re: Dreamer, above...

Its simply a matter of a possible characteristic of lifting injectors, that over time they can develop steam leaks. Across a whole class of locos, the lifting injector can be skillfully managed. it's big advantage, as I've said, is it's superior regulating capabilities when crews want a slow delivery rate of water to the boiler. At full capacity, injectors can flood a boiler with too much water... so, if you're pulling a light train across relatively flat territory using the injector at it's full capacity means constantly starting and stopping the 'gun' to maintain the desired water level. With skillful management of the cold water supply ( trough a valve in the water supply pipe) a fireman can leave the steam flow wide-open, and feed a constant trickle of water into the boiler --- thus easily maintaining the desired water level. Since he "knows the territory" that is coming up, he can gradually change the water feed-rate in anticpation of the coming changes in the grade or operating changes, like station stops. Leaving the injector 'on', as if it were a steam powered water pump, the fireman can skillfully regulate the water level without the necessity to continually have to start, stop and re-start the 'gun'. Some times, he will ask the engineer to run the injector on the engineer's side in anticipation of managing the water level over a rolling track profile territory. Non-lifting injectors became more popularly with the advent of steam operated water pumps and feed-water heaters. The steam pumps can be run at very low pumping rates and then easily go to very fast pumping rates. Fine regulation from a lifting injector became a superfluous nicety, since the gun was used very rarely by crews used to pumping their engines. The greater reliability ofvtye non-lifting guns, made them the go-to design when placing an order fir new locos, or uogradingbolder engines. Another factor was the varying skills of engine crews...they typically wanted to only turn the gun 'on' or OFF, on a more casual basis. Typically, RRs like the PENNSY ordered 1,000 boilers ( of the same design) with half applied to the K4s locos, and the other portion to the L-1, 2-8-2, Mikados. There were thousands of crews running the fleet, with widely varying injector experiences --- so the safe choice for their designers was to specify engines be equipped with non-limiting injectors... Later, the M1 class locos, were designed with Worthington feedwater pumping systems...and they used the non-lifting astge back-water delivery device. Its interesting that ex-CP 1278, 4-6-2, formerly owned by F. Nelson Blount's Steam-powered excursion line at Steamtown, Vermont was modified by the applying a 'bundle-type' Elesco feedwater heater ( usiing the existing pump), and they replaced the original Hancock non-lifting "inspirator" with a large size Edna lifting injector. Maybe they knew of the Hancock's propensity for failures, and wisely chose to use a diffent, lifting -type injector. .... That engine was a wonderful performer --- ranmany sears successfully and then sold to Gettysburg RR, until the boiler was abused by the crew of The Gettysburg RR when they generated a "dropped crown sheet event" in the sipummer of 1996 ... W. Not proofed, yet... Edited 1 time(s). Last edit at 01/16/20 13:17 by wcamp1472. Date: 01/16/20 15:04 Re: Temperature of water in tender affect injector performance? Author: Dreamer The reason I brought up the SP is the SP worked in Eastern California, Arizona, New Mexico, Texas, and Lousiana. In many of these areas the average water temperature can be quite warm. In a Southern Pacific Historical Society Trainline there was a picture of a large number of injectors stacked up. While many railroads were good at getting every penny of investment out of their locomotive and particularly at the end of steam they also had the inventory of spare appliances to repair and adjustmentsor even replace as needed. The organizations today do not have the parts inventory that the railroads did many years ago. The railroads understanding of details was incredible. A prime example of this was the UP have summer and Winter nozzles for some of their locomotives. While Injectors seem to work better with cooler water and cooler ambient temps I wonder about the cone wear and if tollerances were different if the complaints would be the same.

Dreamer |