| Home | Open Account | Help | 293 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Steam & Excursion > Whazzit? (13)Date: 01/17/20 12:07 Whazzit? (13) Author: LarryDoyle Date: 01/17/20 12:12 Re: Whazzit? (13) Author: wcamp1472 Yes.

W. Date: 01/17/20 12:15 Re: Whazzit? (13) Author: LarryDoyle wcamp1472 Wrote:

------------------------------------------------------- > Yes. > > W. LOL! You get an "A" for that one. -John Date: 01/17/20 12:36 Re: Whazzit? (13) Author: wcamp1472 I learned that from Wheelihan...

W. Date: 01/17/20 12:49 Re: Whazzit? (13) Author: HotWater wcamp1472 Wrote:

------------------------------------------------------- > I learned that from Wheelihan... > > W. Thank you! Don't you just LOVE those, "Does anybody know................?" type questions? Of course SOMEBODY knows. Date: 01/17/20 13:11 Re: Whazzit? (13) Author: LarryDoyle OK. So IDENTIFY IT!

Good Grief! (Ohhhh... The things up with which I have to put.) -John Date: 01/17/20 13:23 Re: Whazzit? (13) Author: wcamp1472 Actually, I understand why people use that 'figure of speech'....

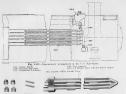

However, when "thrown a slow pitch" like THAT, I can't resist the urge to knock-it-out-of-the-Park. In all honesty, I like LarryDoyle's series about loco appliance oddities.... One that I had not expected, was the Nickel Plate's use of s single feed, miniature, hydrostatic lubricator in the steamline to the pilot-mounted air compressors. A separate oil pump line from the valve-oil mechanical lubricator fed the oil reservoir of the hydrostatic lubricator. There was a small water reservoir incorporated in the casting. In use, the mechanical lubricator pumped oil to the hydrostatic, whenever the engine was moving. When full, the hydrostatic's excess oil simply dribbled into the steam supply to the compressors. The oil feed pump in the mechanical lubricator was adjusted at a very low delivery setting, because it operated continuously. There was no separate feed-rate adjustment in the hydrostatic, it was 'set' at the factory. When sitting around, especially with lots of locos ready and waiting, the "miniature hydrostatic" fed oil to the compressors as they softly idled, many for hours at a time. No attention was need by the hydrostatic... At idle speeds if the compressors, the oil capacity of the 'hydrostatic ' would last a week of sitting around by a loco under steam. It was an ingenious device marketed by Nathan, I believe, that saved many air compressors from "running dry". The little hydrostatic required no attention...it quietly did its job, under appreciated and un-loved. W. Date: 01/17/20 13:24 Re: Whazzit? (13) Author: DWDebs/2472 Front-end throttle plus oddball superheater units. The superheater units were probably touted as easier to remove and install than the usual Type A or Type E... but it sure doesn't look easy to get a wrench in to tighten or loosen the clamp bolts behind the tapered vertical headers. Also these SH units had to be terribly heavy compared to a Type A.

Working inside smokeboxes is not easy. The heat and cinders (or flue-cleaning shots of sand, on an oil burner) during operation quickly strip off any paint the backshop applied during the last overhaul. Every interior surface is rough, rusty, and sooty. There isn't much room to manuever. To work inside, you need the strength of an ox and the physique of an underfed greased weasel. You need a helper just to hand you tools, and half the time the portable drop light is shining into your face. It is not an accident that a "Boilermaker" at the local watering hole is a shot of whiskey with a beer chaser! - Doug Debs Date: 01/17/20 13:38 Re: Whazzit? (13) Author: HotWater I wonder if that is the "inner workings" of that Chambers Front End Throttle" system?

Date: 01/17/20 14:17 Re: Whazzit? (13) Author: LarryDoyle Yes!

When we think of front end throttles and of superheaters we quickly think of the American Throttle Co's (no "Multiple" in their name) American Multiple-Valve Throttle and Superheater Header (the full part name) in conjuction with a Type A or Type E superheater made by The Superheater Company. (Locomotive Superheater Co = L S Co = "Elesco". Get it?). But there were others, as we have seen recently with the Chambers front end throttle. Dodge Steel Company was another one. What we have featured in this thread is one made by the J. S. Coffin, Jr., Company - better known for their unconventional looking feedwater heater. Coffins' Model C-S Superheater and Throttle Valve is shown in my original post and below. It's claimed virtues include: Self draining. There are no reverse upward bends which could collect moisture Compact. Can be installed in less space in the smokebox - a good choice for retrofitting in a small smokebox Each superheater element is identical, reducing inventory of spare parts Each element may be removed without taking out elements above or below Also note that the drawing includes a subtle suggestion to use it with a Coffin feedwater heater. -LD  Date: 01/17/20 14:44 Re: Whazzit? (13) Author: LarryDoyle HotWater Wrote:

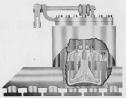

------------------------------------------------------- > I wonder if that is the "inner workings" of that > Chambers Front End Throttle" system? Do you? [Sorry, Jack, I couldn't resist.] [But, I'm gonna show you the "inner workings", anyway.] [<G>] Well, Coffin isn't gonna use a Chambers throttle - Chambers was an Elesco product. But they were very similiar, and basically adopted the double seated pattern of traditional dome throttles. The Coffin C-S Superheater throttle incorporated into the saturated steam header is illustrated below. -John Edited 1 time(s). Last edit at 01/17/20 14:45 by LarryDoyle.  Date: 01/17/20 19:19 Re: Whazzit? (13) Author: patd3985 HotWater Wrote:

------------------------------------------------------- > wcamp1472 Wrote: > -------------------------------------------------- > ----- > > I learned that from Wheelihan... > > > > W. > > Thank you! Don't you just LOVE those, "Does > anybody know................?" type questions? > Of course SOMEBODY knows. My mother didn't know once.............ONCE! Date: 01/17/20 20:29 Re: Whazzit? (13) Author: LarryDoyle wcamp1472 Wrote:

------------------------------------------------------- > > When sitting around, especially with lots of locos > ready and waiting, the "miniature hydrostatic" > fed oil to the compressors as they softly idled, > many for hours at a time. > No attention was need by the hydrostatic... > At idle speeds if the compressors, the oil > capacity of the 'hydrostatic ' would last a week > of > sitting around by a loco under steam. > Why not just turn them off? -LD |