| Home | Open Account | Help | 338 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

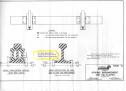

Steam & Excursion > I would like to offer some correct details about driving a spike.Date: 10/13/20 15:45 I would like to offer some correct details about driving a spike. Author: PlyWoody For the last several years I have viewed a number of video of newly built track in museums and I see that we have many very capable young men and even women getting a hold on an air hammer and building track by spiking down the rails. I need not name the locations but they are in New Mexico, many places in Colorado, Pennsylvania, Maine, New York, and other states. I am not being critical of the good work being done but only wish to identify the exact details of the art to truly place the spike in the correct manor so if you match up the actual location of the defect, don’t relay this as a complaint but pass on the correct method. Spike must be exactly vertical: Look at the design of a new spike and you will see a slanted taper on the bottom of the head. This taper match the taper rolled into the base of the rail as seen in the attached diagram by Conrail. Conrail was mostly using the engineering data from Pennsylvania RR. Because of the design of the head of the spike it must be driven exactly vertical, not on any angle. The spike is designed to prevent lateral movement so if the spike is on a 10 degree angle off of vertical, that spike will only be good for 90% of its value, and not 100% that it could provide. It can work up and out of its hole in the wood just because of its angle. One video of a Gardening Company doing track repair work showed them driving many spikes on an angle and over driving and killing some of the spikes. Do not “kill” a spike: A spike must never be driven so hard that the head of the spike is bent up against the rail or plate. Killing the spike damages the spike purpose and loosens the wood fiber that is cut by the point of the spike. Those cut wood fibers should all be facing down and will grab onto the spike to prevent it from coming loose for the next 50 years. When the spike of over hammered, it causes some of those fiber to reverse and break free of holding the spike down. The spike is not to hold a rail down, only to prevent lateral movement, not vertical movement. The most important thing is the final position and placement of the spike: As in the diagram attached, note the railroad requirement that the bottom heads of the spike does not touch the rail or tie plate. There is a gap of 1/8 inch for several reasons. I have learned that 1/16 or in between is okay as long as the spike does not lock onto the rail. The spike is to prevent lateral movement and not to prevent rail movement day and night by temperature change. If you need to hold and prevent rail movement, rail anchors are placed against side of ties to “box” the rail to prevent movement. This is done with all welded rails as the expansion and contraction of rail is compressed and stretched locally by every set of properly placed anchors. If a spike is driven to lock on every rail, it will soon move the tie and slide and twist the tie and cause gauge problems. Twisted ties are hard to fix. OK you may ask, if I’m using a air hammer how do I know when to stop so I get the spike just above the rail? Turns out it works out easier than one would think as the sound when driving the spike with the air hammer (gun) makes a very distinctive sound difference as you near the base of the rail. Immediately stop at the change of the sound, and do not give it any extra hits which I see happening in many of these videos. If you stop and check for that proper 1/8” under the head and experiment a little you can work out how it is with the weight and size of your air hammer or the different air pressure. When you learn the correct sound you can get the spike in the right place every time. Always have somebody preset the spike in advance and hammered down securely so the spike will not shoot out and hit someone. Never have anyone near when you are spiking. Always have a gauge bar on behind your direction of spiking the gauge rail, and also have a gauge tool on the rail in advance of your spiking with someone with lining bars forcing the rail against that gauge tool while you drive that spike. Keep the gauge tool moving just ahead to get good track. The above can be use by non-profit organization as if it was public domain and enlargement of diagram. PlyWoody. The following is a little personal as I built a length of track next to a very nice station for a Historical society. We got a good number of volunteers so I broke it up into two work groups to space people apart. First drill and set the field spike (outside) on the line rail exactly set distance from end of tie and then when that rail is all spiked, you line that rail very straight, preferably before the second rail weight is on the ties. I broke it into two spiking gangs, first doing every other tie, and second gang spiking behind filled in all the remaining ties. That turned out to become a race, I lucked out by having a gal step forward to do the spiking and she was a power house. I believe she said she had just learned it by building a wharf on a river. Next after everyone with lining bars moved the track straight, we began on the gauge rail. This is where we use two gauge tools, one ahead and one behind each new spike, every other tie. Again we began what seemed to be a race, and since it was lunch time I suggested a break. NO WAY, they were on the roll and away we went over 10 rails spiked down between 11 am and 2:30 PM. Then we had lunch and enjoyed photo show by one of the member in the museum. A shale grit was put on the track and leveled up and dressed like the cinder roadbed of the past. Be careful to keep people clear away from the spiker manually driving the spike that can shoot far away and hurt someone. Eye goggles must be used to drive a spike, and absolutely when pulling a spike with a spike puller tool as the neck of old spikes are often worn away and will break and head directly to your eye. I had two trackman, in two years; ask for new goggles as a spike head wrecked their goggle. And they did thank me for being so strict on the use of goggles as they knew from past practice they would have been blinded. Edited 3 time(s). Last edit at 10/15/20 04:09 by PlyWoody.   Date: 10/13/20 16:10 Re: I would like to offer some correct details about driving a sp Author: HotWater Just what does all this have to do with Steam & Excursion???????

Date: 10/13/20 16:38 Re: I would like to offer some correct details about driving a sp Author: 462pacific Try a steam excursion without spikes.

Date: 10/13/20 16:40 Re: I would like to offer some correct details about driving a sp Author: goneon66 lmao...........

66 Date: 10/13/20 17:18 Re: I would like to offer some correct details about driving a sp Author: xrds72 How about doing it the old way? With a spike maul

It's all in the wrist Date: 10/13/20 17:59 Re: I would like to offer some correct details about driving a sp Author: MaryMcPherson Date: 10/13/20 18:36 Re: I would like to offer some correct details about driving a sp Author: wp1801 How useful!

Date: 10/13/20 18:59 Re: I would like to offer some correct details about driving a sp Author: PlyWoody HotWater Wrote:

------------------------------------------------------- > Just what does all this have to do with Steam & > Excursion??????? Hotwater, You always get away with most often critical posts, so I will answer you with an unintended criticism as the East Broad Top Foundation employees need to learn some of the details above and that is a steam railroad and excursion line. I would like to see the work they are doing will last as long as possible. Killing a spike with a air hammer is doing damage. Check out their Facebook page if you want to listen to them spiking down rails. It is easy to hear the results of the work. They have not been trained yet to the art of building track that will pass quality control. Conrail had inspection of every tie gang job and rated every job in competition. Better not have any killed, or worst bent spikes. Edited 1 time(s). Last edit at 10/13/20 19:13 by PlyWoody. Date: 10/13/20 19:41 Re: I would like to offer some correct details about driving a sp Author: railstiesballast Thank you PlyWoody, this is stuff I heard from old heads, from track laborers to Chief Engineers, and it was always taken as a part of the "body of knowledge" that all RR engineering department employees used in their daily duties to run the railroad.

It is kind of embarrassing that the new ways of hiring and training RR employees have missed these skills. Constructive criticism is not always welcome, but it really makes things better. Date: 10/13/20 19:56 Re: I would like to offer some correct details about driving a sp Author: AndyBrown PlyWoody seems to be a magnet for criticism but I admire his verve and habit of not letting the naysayers get him down. Once again he posts an informative and interesting message backed up by obvious knowledge and experience in the subject at hand.

Steam and Excursion is as good a home as any, and probably does reach the widest audience of members who can actually apply the lessons learned. I certainly knew nothing more than "pound 'em in" when replacing ties on our 100 some feet of track at the Wilton (IA) Historical Society. Andy Date: 10/14/20 05:17 Re: I would like to offer some correct details about driving a sp Author: mhcorrigan This is one basic function of track work that most pay no attention to and never think about. As described in your article, there is a science associated with it to do correctly.

Posted from iPhone Date: 10/14/20 06:10 Re: I would like to offer some correct details about driving a sp Author: RRTom Thanks Plywoody.

There is something about driving spikes...Several times with different crews on different rail lines in the 1990s, I saw impromptu competitions, or at least shows of prowess, involving spike driving. Also neat to see was two men alternating spike maul blows on the same spike. One afternoon in 1992 after working with an Amtrak production gang, I saw a Conrail tie gang working and stopped by to say hello to my MOW brethren. I was impressed with their organization. Date: 10/14/20 11:44 Re: I would like to offer some correct details about driving a sp Author: wingomann xrds72 Wrote:

------------------------------------------------------- > How about doing it the old way? With a spike maul > > It's all in the wrist That's ok for a few ties but not so hot for building any real track. Plywoody - good information. This info is right up there with the proper way of rolling tubes. There is a right way of doing every job. It 's up to the old hands to pass the info along. Date: 10/14/20 13:49 Re: I would like to offer some correct details about driving a sp Author: Elesco I have a dumb question. The outside rail in a curve is subject to substantial lateral centrifugal force from the wheels passing over it. With the recommended 1/8" gap between the underside of the spike head and the rail base, what keeps the inside base of the rail lifting off the tieplate with each passing wheel or truck? And if it does lift, isn't something going to eventually wear out?

Edit: Answering my own dumb question, the tip-over point for the rail would be indicated by a force vector approximately as shown by the arrow added to the rail cross section picture. This corresponds to an angle of 31.5 degrees from vertical. I think a locomotive would never tip the rail, because it would tip over itself first. Edited 3 time(s). Last edit at 10/14/20 15:27 by Elesco.  Date: 10/14/20 15:34 Re: I would like to offer some correct details about driving a sp Author: ChrisCampi Driving a spike 90 degrees vertical is hard to do. Even harder for museums who most often are using volunteers, reclaimed ties and spikes. The used ties need plugs to fill in the old spike holes and the spikes, even when new will tend to drift. Mostly due to spike killed holes, with different rail sizes and spike patterns. Reclaimed spikes are most often not straight to begin with and even though efforts are made to straighten them, lead to drifting. Older soft ties are much easier to spike. Hardwood ties much harder. Factor in the inexperienced crews and fatigue, and you'll get some bent spikes and drift. Leaving the spike head resting above the rail base is much easier to control, but surprisingly difficult to get through peoples heads because it doesn't seem natural to them.

It should be noted that aligning the rail is also very important and sometimes driving a spike in at an angle is needed to accommodate that. The technique can also be used to correct gauge problems. It's a tool that has a place used sparingly. Using a spike hammer is naturally much harder then an air hammer, but a eighty pound air hammer and hose gets mighty heavy pretty quickly. Teams of two or three should be employed with the air hammer so one can operate the hammer and another provides hose management. Air hose management makes operating the air hammer MUCH easier. The two can then trade off. This provides for a greater quality of work and speed. I also enjoy Plywoody's posts. Track building is fun, but damn hard work. Date: 10/14/20 15:45 Re: I would like to offer some correct details about driving a sp Author: ChrisCampi Elesco Wrote:

------------------------------------------------------- > I have a dumb question. The outside rail in a > curve is subject to substantial lateral > centrifugal force from the wheels passing over it. > With the recommended 1/8" gap between the > underside of the spike head and the rail base, > what keeps the inside base of the rail lifting off > the tieplate with each passing wheel or truck? > And if it does lift, isn't something going to > eventually wear out? > > Edit: Answering my own dumb question, the > tip-over point for the rail would be indicated by > a force vector approximately as shown by the arrow > added to the rail cross section picture. This > corresponds to an angle of 31.5 degrees from > vertical. I think a locomotive would never tip > the rail, because it would tip over itself first. I'm no expert in rail tipping but you have to factor in gravity and the weight of the locomotive (train) itself. Spikes aren't there to keep the rail from floating away, but to keep it from moving laterally. Also note the drawing. You can see how the tie plate under the rail is thicker on the outside(field) then the inside(gauge) canting the rail head inward. Date: 10/14/20 22:35 Re: I would like to offer some correct details about driving a sp Author: EMDSW-1 Modern production spikers automatically feed the spike in a vertical position. They also drive the spike until it contacts the base of the rail and only the operator through changing sound controls how deep it is driven. Generally the first train over the track compresses the plate to the tie and establishes the 1/8 inch space between the spike and rail.

EMDSW-1 Date: 10/15/20 15:48 Re: I would like to offer some correct details about driving a sp Author: march_hare For what it's worth, I found this post informative and useful. Timely, too, since I'm currently building a short section of track to move my caboose onto.

Thanks for the instructions. Date: 10/16/20 14:17 Re: I would like to offer some correct details about driving a sp Author: Goalieman There is a “science“ to EVERYTHING and I appreciate learning such details. Never considered the fact that the spike was driven solely to prevent lateral movement or the fact that the plate had a built in angle. Thanks to PlyWoody as well as everyone who replied to this post! Very interesting info indeed!!

Posted from iPhone Date: 10/16/20 17:38 Hello COMO, CO Author: PlyWoody Is there anyone here that is connected with the major reconstruction at COMO, CO that might be interested in any of these suggestions? They are starting a new line north of the Station and may be receptive to see if they might be interested to check out their present procedures or may want to adjust to these suggestions.

Laws, CA, may be building more track soon and they might find this information useful. And the Sandy River & Ragingly Lake has an entirely new car barn ready to receive three new tracks this coming spring. They may find these note useful to speed up their track construction. in Louisiana,, at the sawmill served by the Red River & Gulf RR and extensive line is being returned to operation and these direction my help speed up the work. |