| Home | Open Account | Help | 233 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Steam & Excursion > Curiosity - Sealing of Smokebox & Its CoverDate: 11/16/22 18:25 Curiosity - Sealing of Smokebox & Its Cover Author: rrman6 Just recalling the recent accident at Strassburg, PA where the loco cover became pierced by a tractor backhoe.

1.In the case of a steam loco with belching smoke, is the smoke box cover sealed somehow when assembled with all the nuts seen on the face? 2. If no sealant is used at the mating surfaces, what would keep the smoke from leaking between the cover and the smoke box itself? 3. When the nuts are assembled, is there a formed angle iron ring inside the smoke box that has the studs welded to it? Date: 11/16/22 20:25 Re: Curiosity - Sealing of Smokebox & Its Cover Author: flash34 In the old days there would have been an asbestos rope gasket between the door and the smokebox front, which seals air tight when the dogs are tightened down. Now we use some manner of a fiberglass rope or gasket which achieves the same result. You will occasionally see one that leaks, and very possibly also puffs a little smoke in spots. This definitely cuts into the vacuum and reduces the draft, resulting in more smoke.

Date: 11/17/22 00:36 Re: Curiosity - Sealing of Smokebox & Its Cover Author: wcamp1472 I've seen both conditions: Some sealed with a flat ribbon-like door gasket,

and well machined, smooth smokebox doors closed and clamped without a sealing gasket. It's a preference thing. And yes, it's most common that the smokebox front is formed with right-angle 'lip', outward-facing, around the opening. During construction, the row of securement studs are screwed tightly into their mounting holes, not welded. There are Z-shaped small castings on each of the studs called 'dogs', that are securely tightened, after smokebox work or inspections. During servicing of smokebox interiors, the clamping-nuts are simply loosened, and the dogs are rotated 90-degrees, & left loose on the studs.... allowing the door to be opened. Tightness of the dogs is not as important as uniformity of torque pressure used on all the nuts. Uniform pressure, ----evenly snug, but not over-tightened is best. Most common is no door gasket. On British locos, with their attention to machining accuracy, it's common to see a single, central stud in the center of the door, and they never use a door gasket. They typically use two brass nuts, each made with a long handle. The nut closest to the door, pulls the door tightly closed onto the central stud, and the outer nut locks the two nuts securely together. Obviously, the use of the handles on the nuts, means "hand-tightened" only, no wrenches. Typically the two nut-handles wil be found at the 6 o'clock position, when tightened. And yes, the two securement nuts must be removed to open those smokebox doors. W. Edited 1 time(s). Last edit at 11/17/22 00:54 by wcamp1472. Date: 11/17/22 05:57 Re: Curiosity - Sealing of Smokebox & Its Cover Author: bmoore765 Unless the seal is horrible you aren't going to notice a lot of smoke leaks coming out. The real issue is air being pulled into the smokebox which can negatively affect draft. I've heard tale of one railroad (I think NYC or PRR) that actually had a method of doing a hydrostatic test on the smokebox to test for smokebox leakage. If true I'd love to know how that was accomplished.

Date: 11/17/22 07:58 Re: Curiosity - Sealing of Smokebox & Its Cover Author: rrman6 Thanks guys for your responses. Sounds much like what I was thinking of. As for "bmoore's" entry, I'd also be curious due to air leakage through the flues, firebox door, etc. Only if each flue was first sealed in the firebox and at the exhaust stack and then lightly pressurized???? Could this possibly been performed for testing flues for minimal leakage more than for the smokebox?

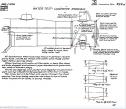

Date: 11/17/22 11:47 Re: Curiosity - Sealing of Smokebox & Its Cover Author: bmoore765 Did some digging during lunch and found the attached. This was apparently a Santa Fe procedure. Not really a hydrostatic test in that the water wasn't pressurized, but everthing inside was blanked off and the smokebox filled with water through the stack to the top to test for any leakage.

Date: 11/17/22 11:49 Re: Curiosity - Sealing of Smokebox & Its Cover Author: wcamp1472 The more likely cause of vacuum 'destruction' are steam leaks in the smoke box,

or through, freeze-busted superheater units.' . Also, steam leaks at the base of the blast nozzle, below the smoke stack, & off-center alignment between the center of the blast nozzle and the center of the smoke stack. Because of many factors, like the smoke stack opening, RRs did not waste time trying to pressure test the smoke box. Besides the access door, the other possible source of leaks are the holes, either side, with the steam delivery pipes to the valve housings on top of the cylinders. Those 2 smokebox holes are a couple of inches larger than the delivery pipes, and the external pipes were fitted with heavy duty 'telescoping' cylindrical jackets covering the insulated external, steam delivery pipes to the cylinders. You don't want the live-steam pipes touching the hole-edges of the smokebox. So, with due care and careful fitting, the air leaks into the smoke box can be eliminated. "Vacuum testing" is not needed, and too hard to test for. "Leaky superheater" units are more likely, and a BIG problem ....mostly because of the immense rate of expansion of the free-steam cloud into the draft psth. A small 1/2" long crack in the return bend of a single unit can destroy the draft of the entire locomotive.. Remember that on most loco modern locos with front-end throttles, that the units are steam pressurized whenever there is pressure on the steam gauge. That's gonna be the source of the biggest drafting problem that you'll experience. W. Date: 11/17/22 16:30 Re: Curiosity - Sealing of Smokebox & Its Cover Author: rrman6 Thanks guys for the futher input. Very interesting! Are any of these leakage detection processes still performed on existing operating steamers in the USA these days?

Date: 11/17/22 16:42 Re: Curiosity - Sealing of Smokebox & Its Cover Author: wcamp1472 There is NO practical need, or use, for such a "water test."

W. Date: 11/17/22 17:19 Re: Curiosity - Sealing of Smokebox & Its Cover Author: LarryDoyle If you ever see pix of smoke emitting from smokebox seams or door gasket, other than the stack, it is proof of serious mismanagement by the enginemen. If the smokebox pressure is not below atmospheric the byproducts of the firebox can only come out through the firedoor in the cab or down through the grate!

-LD Date: 11/17/22 18:10 Re: Curiosity - Sealing of Smokebox & Its Cover Author: rrman6 Then, NOT GOOD! Thanks guys for all the input so far...interesting!

Date: 11/17/22 18:32 Re: Curiosity - Sealing of Smokebox & Its Cover Author: wcamp1472 One time, in Baltimore, NKP 759 while live and awaiting a crew ( 'light' move to Hagerstown),

had a "safe end-ed", 2" dia. boiler tube 'let-go" and separated. It filled the smoke box and firebox with steam and water... the steam pressure in the firebox immediately smothered the fire on the grate ... faster than you can say "Oh-Sugar!" It was a relatively small opening, and eventually all the boiler water, down to that very low level all went on the ground... The same thing as you blowing down the glass chimney of a kerosene lamp... Poof, you blow out the flame. We, then, got the 759 ready to be towed back to Hagerstown... The next morning, before we finished our late AM breakreast, our boilermaker, Joe Karal, at the WM's roundhouse, had been up earlier, had gotten a new 2" flue + boiler tools and had a new tube installed by 10AM... When it let go, the back-draft, down through the grates very quickly extinguished the thin fire...within a matter of seconds.. W. Edited 5 time(s). Last edit at 11/17/22 22:38 by wcamp1472. Date: 11/17/22 18:52 Re: Curiosity - Sealing of Smokebox & Its Cover Author: rrman6 Sounds like the 759 certainly "passed its gas" in a wet and BIG WAY!

Edited 1 time(s). Last edit at 11/17/22 18:53 by rrman6. Date: 11/17/22 20:31 Re: Curiosity - Sealing of Smokebox & Its Cover Author: LarryDoyle Stopping at a station the fireman will immediately turn on the blower. This admits a small jet of steam in the smokebox to be directed up the stack, which reduces the air pressure in the smokebox.

If he fails to turn on the blower, smoke will immediately flow out the firedoor and fill the cab. -LD Date: 11/18/22 09:44 Re: Curiosity - Sealing of Smokebox & Its Cover Author: Drknow wcamp1472 Wrote:

------------------------------------------------------- > There is NO practical need, or use, for such a > "water test." > > W. Wes: Why then did AT&SF specify this procedure? A superstition of the CMO? Just wondering. TIA. Regards Posted from iPhone Date: 11/18/22 11:02 Re: Curiosity - Sealing of Smokebox & Its Cover Author: wcamp1472 Are there any other, similar, 'flooding' tests prescribed by any other

major railroads on the North American continent? Who knows why Santa Fe thought that filling a smoke box with water out the stack, wouls be beneficial. Making, installing, and removing 300 or more wooden flue-plugs would consume a lot of labor hours, for no perceived benefit. No such maintenance pricedure has been documented on the particulars of performing the test, except for the notes on the drawing. The possible leak areas are around the steam pipes to the cylinders, and the smokebox door. Both areas are easy ensure against 'vacuum leaks'. I'd caution against doing such foolishness. What waste of time. W. Date: 11/18/22 11:30 Re: Curiosity - Sealing of Smokebox & Its Cover Author: LarryDoyle Perhaps the date of the drawing should be not Aug. 1, 1928, but rather Apr. 1, 1928.

-LD Date: 11/18/22 12:44 Re: Curiosity - Sealing of Smokebox & Its Cover Author: bmoore765 LarryDoyle Wrote:

------------------------------------------------------- > Perhaps the date of the drawing should be not > Aug. 1, 1928, but rather Apr. 1, 1928. > > -LD It's real. I've heard this talked about before and I'm almost positive that there are photographs out there of either a PRR or NYC locomoitve undergoing a water test. It could be one of those processes developed just for the sake of having a process although that seems to be more of a modern day phenomenon. I agree that there seems to no real benefit over the time and cost to carry this out. |