| Home | Open Account | Help | 375 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Steam & Excursion > Stoker vs Human QuestionsDate: 06/21/17 07:59 Stoker vs Human Questions Author: Tominde This topic is geared toward "back in the day" and is geared toward smaller or medium size coal burning engines such as 2-8-0 or 2-8-2 or 4-6-0s in commuter service. I know some 2-8-2s got used in heavy or high speed freight but that's a different ball game.

Which was more fuel efficient, stokers or hand fired engines? Would a good fireman be able to build a better fire by hand than by stoker? A good fireman would do both. Which was easier on fireboxes? On hand fired engines did opening and closing firebox door frequently impact fuel efficiency? I suspect there are too many variables to really accurately compare. I also understand that some roads required 2 fireman by union agreement if the tonnage on hand fired trains exceeded certain limits. Date: 06/21/17 08:51 Re: Stoker vs Human Questions Author: upheritage6 Depending on the size of the engine

Now a Big Boy not even a crew would be able to cover to whole firebox And they would have to shovel from when they started to whe thet ended their shifts. It was designed to where the jets when they shoot the coal into the box, the coal covers much more surface. I Dont think opening the doors would decrease fuel efficiency. By much anyway. All the fire is doing is boiling water. Not much heat leaves in that time,. It does put more draft on the fire. Not a good fireman could fire a 4-8-8-4. Possibly a 4-8-4. But shoveling coal into a box isnt too hard. Maybe two fireman could do it easily. But then again, the size of the firebox matters. Posted from Android Edited 1 time(s). Last edit at 06/21/17 08:52 by upheritage6. Date: 06/21/17 09:05 Re: Stoker vs Human Questions Author: Realist The PRR did some well-documented tests on K4s at their Altoona test plant. They tested hand-fired vs. stoked-fired K4s and what they discovered was that the stoker really unleashed the power of that boiler. IOW, it was virtually no contest.

Date: 06/21/17 09:36 Re: Stoker vs Human Questions Author: dsrbc My great uncle shared a story that a few times on a CB&Q O5 that when the stoker was broke down and they would still send the locomotive out, and that three fireman were assigned to the run. A Hudson they could keep up, an O5 it was a struggle. I would imagine the firemen were glad when the run was done.

Edited 1 time(s). Last edit at 06/21/17 10:11 by dsrbc. Date: 06/21/17 09:44 Re: Stoker vs Human Questions Author: wcamp1472 Here's some thoughts...

I don't know about Union agreements, so I'll stay away from that... Maintaining the fire bed is the key.... Older, smaller fire boxes tended to be narrow and deep, located between the drive wheels .. 2-8-0s, etc. so their fires were deep, narrow and long, about 100 miles was a day's work, so the grates could stand to last for that period, before getting so deep in ash that no air could get to the fresh coal. Note: NEVER, EVER shake the grates or dump live-fire into the closed ash pan.... When 'cleaning' any fire, always be sure to clear away my hot coals from under the iron grates , and out of the ashpan.... The hot coals will quickly melt and burn the grates and supports --- dropping the fire into the pan. Then cold air rushes in above the fire and cools the boiler down... As the limits of the narrow firebox became reached--- both in human firing capacity, and in train weights being hauled, the natural progression led to moving and enlarging the grate area--- this, steel being weak , necessitated the improvisation of a 'trailer' axle and wheel-set to carry the weighty firebox. However, the drafting changed from deep narrow fires, easily hand fired, to wider, thinner fires, over a larger surface area.... so shoveling became a matter of smaller scoop sizes, more frequently spread... At about this time, early 1900s, the Schmidt Superheater came into popular application... That was the GAME CHANGER!!! Superheated engines, ran better, hotter and burned less coal and water.... Soon keeping-up, hour after hour, mile after mile.. soon taxed the limits of human sustained capacity... The D&H RR, favored hand fired freight & pass, Anthracite fired engines... Their tests revealed that over an average working day, a human fireman could sustain a 2,000hp boiler load... Over that, they could not keep-up.... Passenger trains, of the WW1 era, tended to be smaller and more easily hand fired--- in fact, the PRR designed the class K4, as a hand-fired design... The first variants were all built as "hand-bombers" they eventually grew to 500 locos in the class, but the rapidily-perfected Archemedes Screw-fed stokers, soon were so good and hot that the PRR changed the design to incorporate the stokers. Early stoker designs were clumsy, unreliable, easily broke and hard to manage ... It took along time before the straight forward, reliable locomotive stokers became adapted.. Soon, on the freight-side, the limits of the super-sized, Big Mikes (2-8-2s), were reached--- and Lima Loco developed the 4-wheel trailer truck ( and frame-extension).... The era of the cast, one-piece, "engine-bed" was still a decade in the future... The trailer truck extension that Lima first used, was a box-like structure that carried the loco firebox, grates & drawbar pin and dragged all the train weight by the trailer truck frame---- well, you can immagine what a mile-long string of freight cars did to that poor trailer truck frame... Year after year... However, in the 1920s, Lima had no choice, as they expanded their Big Mikes, into the 2-8-4.... David P. Morgan, in 'Steam's Finest Hour', tells the story of the steam trials over the mountains between Albany, NY and Boston.... The single, 2-8-4 Lima Demonstrator, took a train that was normally hauled by double-headed Mikes, over that mountainous route... It single-handedly took that train over the mountains, it did it FASTER, burned less coal and water ( than a single 2-8-2) and did it FASTER than the two Mikes ..... This was born: Super Power, snd they called it the Berkshire!!! In honor of the mountains that she gobbled-up.. So, now the freights really began to ROLL... Erie RR really grabbed onto the Berkshire design with a vengeance ---- they ran them FAST, too..... There is no way a hand-fired grate can deliver the sustained, extreme firing-rates needed by SuperPower engines.... Super power engines' furious draft rates burn most of the coal-fines as if it were 'droplets'of liquid--- these fines burn in mid-air, even at draft rates of 200 mph, though the firebox, over the brick arch and through the tubes ...the hottest heat comes from the heat of radiation, convected does the units and conducted is done through the firebox sheets.. Soon, small-drivered Berks, were shaking their frames so bad, at high track speeds, that a solution had to be found---- The problem centered around the two rear drive axles --- they were coupled, so that the two together, shared the counterweights of what normally would be carried on a single driver--- to make the shaking problem worse, ----was the fact that the two rear drive axles were very near the center-of-gravity of the whole locomotive----( just ahead of the firebox and under the belly of the boiler.... In aircraft design, whatever affects the center of gravity, even slightly, affects the whole airframe.... Locos share the same physics... But, the further away from the C-O-G, the imbalance is located, the less the imbalance affects the C-O-G, the less it affects whole structure..... For locos, the solution was to move the Main driver, forward, one axle--- to have the pistons Apply the power to driver-set no, 2..... However, now you've got a very short main driving rod---- So, they had to move the drive cylinders ahead, to lengthen the Main Rod. Now, the two-wheel pilot axle could not carry all that extended weight... Ergo the 4-Wheel pilot truck. Northern Pacific bought the first copies--- thus, was born the "Northern" name for the 4-8-4 types.. The bigger diameter drivers of the 4-8-4s allowed for higher track speeds, smaller counterweights and lighter reciprocating ( back-and-forth motion) parts,,, Back to stokers... The huge grates could only be fired by a power stoker....but, that was only required for maximum loading and uphill fights . Only a limited amount of time is the loco fully taxed at so high firing-rates, are rarely consistently used. The key, is the proper shape of the firebed and the varying depth of the bed, according to the varying draft rates --- depending on the steam consumption... High steam usage requires different condition bed, than low firing rates ... And a crucial factor to proper drafting is matching the draft to the intended, typical daily demand for the boiler use.. A Big Berk drafted for 90-or so cars, is balky to fire with only a few ( under 25) light coaches... There's not enough draft provided by the trailing load, so smoking is an unavoidable consequence ... depending on the style of firing, being used... In actuality,- good firemen, use many techniques to keep the fire lively; but, not too hot--- with low steam-use, the safeties are up, way too often.. wasting water, coal and labor. Efficiency is not dependent upon the method of delivery, it is the skilled use of the power stoker, the team work, over the road, and the proper weight of train, matched to the capacity of the grate, that yields to greater "efficiency", So, skilled firemen today, do a lot of scoop-work, to keep the large grate adequately fed, and brght, but not smoky. Skilled scoop-work does NOT mean, big, mounded, weighty scoop-fulls, but partial scoops well placed, using larger lumps of coal .... The larger lumps burn longer, and produce a less hot fire... I'll add more as questions and comments arise.. W. Posted from iPhone Edited 4 time(s). Last edit at 06/21/17 10:49 by wcamp1472. Date: 06/21/17 10:12 Re: Stoker vs Human Author: timz > Which was more fuel efficient, stokers

> or hand fired engines? No one's ever claimed a stoker was more efficient than a good human, have they? Date: 06/21/17 11:02 Re: Stoker vs Human Author: sgriggs timz Wrote:

------------------------------------------------------- > > Which was more fuel efficient, stokers > > or hand fired engines? > > No one's ever claimed a stoker was more > efficient than a good human, have they? I have read that the combustion efficiency of hand-fired engines was slightly higher because the stoker screw action tended to create fine coal particles that were easily carried out of the firebox by the draft. Hand firing was less likely to do this, and you ended up with a slightly greater percentage of the coal landing on the grates where it could burn completely. Scott Griggs Louisville, KY Date: 06/21/17 11:14 Re: Stoker vs Human Author: crackerjackhoghead I believe, at some point, the unions got an agreement that, any engine over 80 tons had to be equipped with a stoker.

On the Northern Pacific, as engines got bigger and bigger (were talking about Mikados), the crews began complaining that they had to "baby" the engine because the fireman could not keep up. The company insisted that that was nonsense and that stokers were not needed. To prove their point, they ran a test train, from Auburn to Ellensburg, with managers on board, and the engineer was instructed to not hold back any. During the trip, the fireman, a man in his early twenties, shoveled something like 24 tons of coal. The next morning, the crew caller found him dead in his room!. All future locomotive orders were equipped with stokers. Date: 06/21/17 11:17 Re: Stoker vs Human Author: HotWater sgriggs Wrote:

------------------------------------------------------- > timz Wrote: > -------------------------------------------------- > ----- > > > Which was more fuel efficient, stokers > > > or hand fired engines? > > > > No one's ever claimed a stoker was more > > efficient than a good human, have they? > > > I have read that the combustion efficiency of > hand-fired engines was slightly higher because the > stoker screw action tended to create fine coal > particles that were easily carried out of the > firebox by the draft. Hand firing was less likely > to do this, and you ended up with a slightly > greater percentage of the coal landing on the > grates where it could burn completely. > > Scott Griggs > Louisville, KY Well, I sort of wonder about THAT. Maybe I'm wrong in thinking this, but LOTS of the coal blown into/onto the fire of a "modern coal burning Super Power steam locomotive" does indeed burn prior to "hitting the grates", i.e. in mid air above the fire bed. An interesting comparison would stationary boilers that are fired with darn near coal dust, similar to an oil flame. I remember firing NKP 765, back in the early 1980s, and the idea was to keep a nice thin fire, and allow the crushed coal from the stoker and the distributing jets to blow the coal evenly OVER the fire, and burning in "mid air". Thus, if one "did it right", the actual fire-bed would go out within 5 minutes or less, when you stopped. Wes Camp should have more on this. Date: 06/21/17 12:36 Re: Steam vs Human Author: spnudge In 67 I was assigned to "C" Company, 714th Battalion of the TBROS&DE. I showed at supply and they gave me my 45 holster, liner, pocket watch, etc and the last item was a new shovel. I told the guy I didn't fall for that crap, steam engines were long gone from the railroads. He told me to sign for it and move along.

The next morning I was down at Hanks yard looking at a steam engine, that wasn't long gone at all. It was hot, dirty and I was to learn how to be a fireman. I fired and ran 2-8-0s in the Army, (along with a bunch of different diesels). They were coal burning, hand fired. Some of the lifers knew how to fire them and would show us, otherwise it was the guy ahead of you showing you the ropes. It took awhile to be able to keep a hot enough fire to make it half way around post to King Jct. before the air pumps quit and you came to a stop. Then you would start all over getting the steam back to 200 lbs to get back to Hanks yard. Pretty soon I was qualified as an engineer and thought I knew it all. I busted my ass as a fireman and thought that was the nature of the beast. Had an E-6 from Germany ride with me one day. We left Hanks Yard for King and were banging along when he came over to me and yelled why was I working the fireman so hard. I told him that was the way I was taught. He reached over and grabbed the reverse lever and started hooking it up, pulling it back towards center. Well, we took off, the steam hit the pops and the fireman was sitting down, all the way around post. The E-6 sat me and a few others down that afternoon and explained what was going on in the operation of a steamer. I had been there a year and was never taught anything about steam until then. Just copied what we had learned before. An education. Nudge Date: 06/21/17 12:48 Re: Stoker vs Human Author: sgriggs HotWater Wrote:

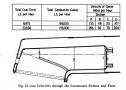

------------------------------------------------------- > sgriggs Wrote: > -------------------------------------------------- > ----- > > timz Wrote: > > > -------------------------------------------------- > > > ----- > > > > Which was more fuel efficient, stokers > > > > or hand fired engines? > > > > > > No one's ever claimed a stoker was more > > > efficient than a good human, have they? > > > > > > I have read that the combustion efficiency of > > hand-fired engines was slightly higher because > the > > stoker screw action tended to create fine coal > > particles that were easily carried out of the > > firebox by the draft. Hand firing was less > likely > > to do this, and you ended up with a slightly > > greater percentage of the coal landing on the > > grates where it could burn completely. > > > > Scott Griggs > > Louisville, KY > > Well, I sort of wonder about THAT. Maybe I'm > wrong in thinking this, but LOTS of the coal blown > into/onto the fire of a "modern coal burning Super > Power steam locomotive" does indeed burn prior to > "hitting the grates", i.e. in mid air above the > fire bed. An interesting comparison would > stationary boilers that are fired with darn near > coal dust, similar to an oil flame. > > I remember firing NKP 765, back in the early > 1980s, and the idea was to keep a nice thin fire, > and allow the crushed coal from the stoker and the > distributing jets to blow the coal evenly OVER the > fire, and burning in "mid air". Thus, if one "did > it right", the actual fire-bed would go out within > 5 minutes or less, when you stopped. > > Wes Camp should have more on this. The references I have read suggest that fine particles of coal caught in the draft of a locomotive firebox do not have time to fully burn before they enter the flues. This is different than in stationary powerplant applications (some of which use pulverized coal) because stationary plants are not constrained by the loading gauge size limits on steam locomotive boilers. Stationary boiler fireboxes can be built large enough to keep the draft velocities very low and avoid entraining fine particles such that they are carried away before burning. The attached diagram comes from Ralph Johnson's "The Steam Locomotive". It shows flue gas velocities at various points in the firebox of a Pennsy M1a locomotive under test. Speaking to this subject, Johnson writes, "At high firing rates this velocity reached a figure of 263mph over the arch. A particle of fine coal caught in this gas stream will pass through the firebox in 0.1 second and this is one of the reasons for the great loss of carbon at high-capacity operation. In stationary practice the velocity of the gases entering the tubes is about 10mph at a maximum". So, my comment about stoker firing being slightly less efficient than hand firing was based on the premise that stoker firing produces more fine coal particles than hand firing, and that steam locomotive fireboxes in general operate at high enough draft velocities to carry out a fine particle of coal before it has had the opportunity to burn completely. Scott Griggs Louisville, KY  Date: 06/21/17 12:52 Re: Steam vs Human Author: YardGoat spnudge Wrote:

------------------------------------------------------- > In 67 I was assigned to "C" Company, 714th > Battalion of the TBROS&DE. I showed at supply and > they gave me my 45 holster, liner, pocket watch, > etc and the last item was a new shovel. I told the > guy I didn't fall for that crap, steam engines > were long gone from the railroads. He told me to > sign for it and move along. .... > Nudge Interesting read. Mike Soriano Denville, NJ Date: 06/21/17 13:26 Re: Steam vs Human Author: tomstp It has been written that on Tennessee Pass a D&RGW L-131 2-8-8-2 at 10-15 mph had a draft so hard that 1/3 of the coal put in the firebox never ignited because it was sucked out of the firebox before it could lite.

Date: 06/21/17 14:00 Re: Steam vs Human Author: HotWater tomstp Wrote:

------------------------------------------------------- > It has been written that on Tennessee Pass a D&RGW > L-131 2-8-8-2 at 10-15 mph had a draft so hard > that 1/3 of the coal put in the firebox never > ignited because it was sucked out of the firebox > before it could lite. Then again, there would be no way for one, or even two, humans being capable of maintaining such a high delivery rate. Date: 06/21/17 14:28 Re: Steam vs Human Author: wcamp1472 Ralph Johnson is an unimpeachable source.

A lot of the information about boiler operation, that he references, derives from the extensive, well researched and extremely well documented efforts yielded by the years of research and testing conducted at the Locomotive Test Plant facility at PRR's Altoona, Pa. works... However, even for the M1 illustrated, there is no way that those high firing rates could be attained, or sustained by human work, ..... let alone, handle the operation of the fire doors. 23,000 lbs of coal, in one hour--- thrown into a firebox....gimme a break ....what "efficiency" ??? What's the capacity of an M1 tender? Darned near 24 tons....who's gonna run from the back of the tender , during the last half of an hour test, open the fire door, throw in the coal and run back again? A whole tenderfull of coal, in ONE HOUR??? What possible kind of hand-fired 'efficiency' could you expect??? The firebed would probably be 3 feet deep, and virtually no draft....by the end of one hour, at that theoretical capacity... However, the tests were done for short periods, at specific feed rates, then extended and expressed in coal-rate fed per unit of time...( pounds per hour) So, at high firing rates, you get those results.... fine for the Lab, or esoteric philosophy; but, in real life, a lot of the calculations were performed in order to design a better draft rate for practical use. ( Grate areas, gas capacity through the flues, draft rates, front end, exhaust nozzle/ stack design design etc..) Woodward, of Lima, favored the 4-wheel trailer truck, and bigger, in order to support a large area grate.... his draft velocities were lower because he had larger grate areas and bigger diameter boilers. When Pennsy adopted the C&O T1, 2-10-4, [ under the rules of the WPB].into their J1, they found out just how far loco design had advanced from their coilstered world. In fact, the C&O T1 design was considered a relic of the past, when Chessie sought to up-grade to more powerful locomotives...... Thus, was born the 2-6-6-6, tested at the Altoona Test Plant at 8,000 drawbar horsepower..., without using ridiculous firing rates.... .Now there's a BEAST...it was Lima's BEST... Don't even think about hand firing an M1a, or anything greater than a 2,000 hp, capable loco. An M1 was easily capable of 3,500 to 4,500 hp, ---- you ain't gonna fire THAT, at its maximum rate--- BY HAND!!!! A railroad has three track profiles : up hill, down hill, and virtually FLAT. The uphill/downhill scenario is a 'zero sum' equation. Most of the times, the train is going on flat terrain, or down hill,---- ONLY a short time is spent at high draft rates produced during an uphill climb. Remember, the draft through the fire is totally dependent on the amount of "load" behind the tender---- the crew is powerless to change that!!! In fact, down hill, the load is shoving the engine, the "towing load" is NEGATIVE ...what's the draft in that case??? Firing an engine DOWN HILL, a coal burner, is the hardest challenge. The fireman must maintain high boiler pressure for snappy air compressors, the Main Reservoir pressure must be maximum, to responsive releases, and aiding in re-charge time for the car's auxiliary bresevoirs, the water level in the boiler must be optimally maintained, but you're not using very much steam, the cylinders must be filled with steam, each stroke --for lunbication and positive pressure up the blast pipe ( negative pressure in the exhaust passages, sucks soot and cinders into the cylinders, ruining the oil film and wearing out the cylinder packing ( piston rings) .... you have only the locomotive's blower, the artificial draft, up the stack ( 5% of the normal draft) , and very smoky coal. Firing virtually smokeless, down hill for long grades, requires the best of firing arts.. [Some time, I'll tell you about firing down hill on the WM Ray, down into Connellsville, PA. It took about an hour, maybe longer, to make the descent The Road Foreman gave me very direct instructions, and expected NO problem ...... at the end he was very pleased....and not given to praise, very often...] Flat-land running is easy, but the train is rolling as fast as the engine, so very little HP is actually consumed across the flats...Low firing rates and low draft rates are the rule...it still takes skill to fire well, even in those conditions ... Uphill, is the EASIEST, for stoker fired engines--- all ya gotta do is match the coal-feed rate, to the draft rate, and you'll have the pops up, in no time.. With today's fan-trip coal, it's easy to fire and make all sorts of heat.. Study the texts and the test reports well, but remember they were finding the limits of capacity, for design purposes ..not running trains over the road... W. [As an aside, I have not yet found a RR, steam-era TEXT, that accurately explains how to fire a modern, Big- boilered engine the BEST, EASIEST AND MOST EFFICIENT , sustainable manner. All of their texts concern hand firing, and even then the texts do not cover common conditions, or track profiles... For me, The best sources were the NKP crews I met, The NYC Crews I met, the N&W guys, the Wild Mary crews, and the experts on the C&O. What they cumulatively taught me was the BEST methods--- but, the lessons were ALL the SAME....Virtually no difference, regardless of the Carrier..] Edited 1 time(s). Last edit at 06/21/17 17:51 by wcamp1472. Date: 06/21/17 14:37 Re: Steam vs Human Author: wcamp1472 Looks like the PRR M1 classes used 70 sq ft grates......

The NKP Berkshires used 100 sq ft grates... ( but, interestingly, only 25" bore cylinders...flat-landers, for sure..) Duh.... W, Date: 06/21/17 14:47 Re: Steam vs Human Author: Txhighballer My great uncle hand fired 900 Class 2-10-2's up Raton Pass. Most times, there were two firemen called, but one man could barely keep up. In fact, my great uncle was insulted when they called two firemen on his run! From what I remember, their and the 1600's ability to "eat" firemen caused the ATSF to turn them into oil burners and save on the crew expense.

One other thing that I was told. Hand bombers used less coal than stokers for the same horsepower. I believe this was in tests on the 3400 Class engines. Date: 06/21/17 15:03 Re: Steam vs Human Author: wcamp1472 I will correct R.W. Johnson on his calculations... about cinder dwell-time in the fire box....

He states the velocity ----at the narrowest area, at the top of the brick arch, as very fast, ----- yet, as plainly drawn, the huge volume increase , downstream, from that restriction allows the gasses to expand and thus, the velocity to severely drop... also, the velocity continues to drop, upon entering the flues...and around the units... Yes, at the top of the brick arch, the speed is .1 sec,; but, not the rest of journey through the boiler... Yes, over-firing does reduce efficiency, and so does feeding too much coal...the ART, is in the Balance.. And , yes, ya gotta question even the authors & engineers, on their assertions, ----- when those assertions are confusing & not well defined.... [I was an irreverent, trouble-maker in school, too....] W. Edited 1 time(s). Last edit at 06/21/17 18:54 by wcamp1472. Date: 06/21/17 16:48 RE; 4-8-8-4 Author: Bob3985 I knew an engineer who ran Cheyenne to Rawlins and he told me about the time he was a fireman on a 4000 class 4-8-8-4 with a drag freight. Just west of Hanna the stoker broke and so they limped the train into Hanna into the south Siding. At that point they got permission to continue on to Laramie (which was their home terminal back then) and so he hand fired the locomotive into Laramie. Albeit they were without train but he did get it in to the Laramie shops for repair. The other option would have been to let it die down and tow it into Laramie on another freight. I think Dillard passed away a while back.

And that's the rest of the story. Bob Krieger Cheyenne, WY Date: 06/21/17 17:41 Re: RE; 4-8-8-4 Author: spnudge I forgot to mention about the firebox door and the shovel. When an engine was working and the door wa open, all you saw was white. You had to use your shovel to direct the air in order to see where the holes in the fire were and klinkers. The 612 had a butterfly door with a tredel, the 606 just had a door you swung open with the shovel. Having the door open too long put cold air on the flues.

Nudge |