| Home | Open Account | Help | 234 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Steam & Excursion > She's Quite A Beast To Send Up On A Branch Line Like This One!Date: 09/23/18 04:02 She's Quite A Beast To Send Up On A Branch Line Like This One! Author: LoggerHogger The Milwaukee Road was known for having arrived out West after the other major railroads had already staked their territory in this part of the country. However, even with that disadvantage, the Milwaukee did have some profitable sections of track. We see one of those here.

This ALCO-built brute of a 2-6-6-2 in the form of Milwaukee #9602 is stopped at Morton, Washington in 1937. The Morton Branch of the Milwaukee was the former Tacoma Eastern RR that departed Tacoma and ran south to the logging town of Morton. Along the way were many other mill towns that supplied the Milwaukee with trains of lumber and logs to the extent that big mallets like #9602 were need as motive power. Today the line is owned by Tacoma Rail and a portion of it is home to the Mt. Rainier Scenic RR and Logging Museum. The track from Mineral to Morton has not been used for a number of years and several portions of it are laying in the bottom of the river as a result of numerous washouts. In its heyday, this was quite a branchline. Martin Edited 5 time(s). Last edit at 09/23/18 04:13 by LoggerHogger.  Date: 09/23/18 04:53 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: zoohogger Thanks for that photo, Martin. I’m trying to imagine watching that “monster” come up the hill into Mineral.

I see a passenger car back there. Did they run mixed trains or maybe this was a special? Rick Zorko Date: 09/23/18 04:55 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: LoggerHogger Rick,

This was a special. Martin Date: 09/23/18 06:56 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: A-1 I always thought they needed a Mallet at Mineral. Even if just for display at the museum now.

Posted from Android Date: 09/23/18 08:06 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: fehorse1 When I was involved in the ownership of Rayonier #8, a 2-6-6-2T, we offered it to Mineral. But Tom Murray just wasn't interested in a mallet!

Pete Replinger Date: 09/23/18 10:17 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: LoggerHogger fehorse1 Wrote:

------------------------------------------------------- > When I was involved in the ownership of Rayonier > #8, a 2-6-6-2T, we offered it to Mineral. But > Tom Murray just wasn't interested in a mallet! > > Pete Replinger That's interesting. Tom said he had been promised Weyerhaeuser 2-6-6-2T #108 along with the Lidgerwood but they ended up giving #108 to Snoqualmie. Tom said he was very upset over that as he had been promised #108 and he wanted her. I do know that he turned down the donation of Rayonier 2-6-6-2 #38 as he felt it was too big for MRSR. Martin Martin Date: 09/23/18 10:21 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: Mgoldman LoggerHogger Wrote:

------------------------------------------------------- > The Milwaukee Road was known for having arrived > out West after the other major railroads had > already staked their territory in this part of the > country. However, even with that disadvantage, > the Milwaukee did have some profitable sections of > track. We see one of those here. > > This ALCO-built brute of a 2-6-6-2 in the form of > Milwaukee #9602 is stopped at Morton, Washington > in 1937. > > Today the... For a split second - maybe a bit less than that, I thought you were going to say... Oh, well. There are six Milwaukee Road survivors - according to Wiki, anyway - (who knew?) Wild shot - amazing once was railroad! /Mitch Date: 09/23/18 10:24 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: wcamp1472 One for LarryDoyle...?

Looks to be a soaker? Thats an unusual eccentric crank positioning, for a piston valve, on the rear engine. Looks to be ‘outside admission’ piston valves... Strange loco arrangement...? W. Date: 09/23/18 14:01 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: LarryDoyle wcamp1472 Wrote:

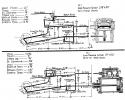

------------------------------------------------------- > One for LarryDoyle...? > > > Looks to be a soaker? > The Milwaukees first 25 2-6-6-2's, class N1, were built as saturated engines, but later 23 were rebuilt with 45 element superheaters. Still later, 17 were rebuilt to N3 class simple engines. The N2 class, 11 engines of which this photoed engine is a member, were like N1 except built with 38 element superheaters. > Thats an unusual eccentric crank positioning, for > a piston valve, on the rear engine. > Looks to be ‘outside admission’ piston > valves... > Strange loco arrangement...? > The front valve gear is set up for direct action (radius bar in lowered position for forward) and the rear engine is indirect action (radius bar in raised position for forward), requiring that the eccentric crank on the rear engine leans back as you have detected. Rear combination lever is set up for inside admission. Front combination for outside admission. Here's a copy of Bill Wilkersons sketches of the valve gear, Note that the bell cranks on the reach rods get inverted. -Larry Doyle Edited 2 time(s). Last edit at 09/24/18 14:08 by LarryDoyle.  Date: 09/23/18 16:04 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: wcamp1472 In the upper drawing, I’m confused by the labeling of the space between the rings (and lobes) of the spool valve.

?Is the spool valve “outside” admission or inside “admission”? (“ inside” : being boiler pressure between the two larger ends of the spool...). W. Date: 09/23/18 17:21 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: LarryDoyle I find the text of Wilkersons explation of the valve gear a bit confusing, as he confounds the difference between "insid/outside admission and "direct/indirect" action. He states "With indirect valve motion, the boiler steam was on the outside, or with a D valve it was on top to keep pressure on the slide valve to insure a proper seal." The upper valve gear drawing is clearly set up for indirect action of an inside admission locomotive, but the cylinder/valve drawing is incorrect.

The combination lever for the upper drawing is set up for inside admission, but it appears the artist put it together with a generic piston valve sectional drawing. but one that shows outside admission. (Also note that the position of the piston and D valve in the slide valve engine does not match the position of the main pin and radius bar.) -Larry Doyle Edited 2 time(s). Last edit at 09/23/18 17:39 by LarryDoyle. Date: 09/23/18 18:51 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: wabash2800 But no Milwaukee Mallets?

Victor A. Baird http://www.erstwhilepublications.com Mgoldman Wrote: - > Oh, well. There are six Milwaukee Road survivors > - > according to Wiki, anyway - (who knew?) Date: 09/23/18 20:40 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: Earlk The rear engine unit is set up for inside admisson valves, but the valve gear is set up for indirect motion, in that the valve stem moves in the opposite direction of the eccentric rod in forward motion. The front unit is outside admission slide valves with direct moton, but the eccentric crank is set 90 degrees back to make te motion work.

It was common for early Mallets to have one engine in direct motion and the other in in-direct motion. One set of vavle gear would be pulling up on the radius rod and othe other set would be pushing down on the radius rod. This was balancing move, so the reverse gear did not have as much load on it. Date: 09/24/18 00:30 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: wcamp1472 O.K....

I get it NOW. They wanted to “balance the load” carried by the reverse- control lever and wanted to reduce the forces on the quadrant’s latch mechanism, in the cab. So, both eccencetric cranks are each tilted in the opposite positions of ‘conventional’ engines where forward motion has the link blocks in the lower half of the link slots... ( At least where I would expect to ‘see’ the arrangement ). So, were the engines’ link blocks and radius bars operated only by man-power, or were the ‘rock shafts’ on these engines moved by air operated power reverses? Typically, the rock shafts are ‘balanced ‘ by a short lever (welded) to the bottom of the rock-shaft. The lever was typically centered between the frames, and a balance spring-shaft ( for spring compression) was surrounded by a large coil spring, with the outer end of the shaft bearing on the compressed spring. The inner end of the coil spring’ compression force was carried by a frame mounted plate —- with a hole for the spring shaft. The compressive force of the balance spring was sufficient, that, if disconnected from the reverse cylinder’s reach rod, the weight of the two rear ends of the radius rods was virtually balanced. And the ( freed of the influence of the power reverse) “lay shaft” would ‘self- center’ the link blocks in the approximate center of the link slot... So, in these engines, the rock-shafts might NOT have used centering springs. In the drawings there are no centering springs shown. But there also is NOT shown a power reverse cylinder. W. Yes, the lower drawing should have the piston at the approximate mid-point of the cylinder, since the crankpin is near the 6 o’clock position if the crank circle.... The drawing’s placement of the piston at the front dead-center makes no sense, at all. OH, well who but us nit-pickers even cares, after all these decades... Edited 2 time(s). Last edit at 09/24/18 07:15 by wcamp1472. Date: 09/24/18 08:34 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: LarryDoyle wcamp1472 Wrote:

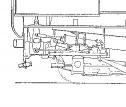

> Typically, the rock shafts are ‘balanced ‘ > by a short lever (welded) to the bottom of the > rock-shaft. The lever was typically centered > between the frames, and a balance spring-shaft ( > for spring compression) was surrounded by a large > coil spring, with the outer end of the shaft > bearing on the compressed spring. The inner end of > the coil spring’ compression force was carried > by a frame mounted plate —- with a hole for the > spring shaft. > > The compressive force of the balance spring was > sufficient, that, if disconnected from the reverse > cylinder’s reach rod, the weight of the two rear > ends of the radius rods was virtually balanced. > > And the ( freed of the influence of the power > reverse) “lay shaft” would ‘self- > center’ the link blocks in the approximate > center of the link slot... First picture shows a leaf spring variation of the spring balance feature for the tumbling shaft Wes described. I've got a drawing or photo somewhere that shows the coil spring version but couldn't find it this morning. Anyway, the reader should get the idea of how it served it intended purpose. I don't know if these Milwaukee engines had a spring balance. > So, in these engines, the rock-shafts might NOT > have used centering springs. > In the drawings there are no centering springs > shown. But there also is NOT shown a power > reverse cylinder. The builders photo shows a manual Johnson bar reverse lever and reach rod. > W. > > Yes, the lower drawing should have the piston at > the approximate mid-point of the cylinder, since > the crankpin is near the > 6 o’clock position if the crank circle.... > > The drawing’s placement of the piston at the > front dead-center makes no sense, at all. > OH, well who but us nit-pickers even cares, after > all these decades... NIT_PICKER ALERT: The upper drawing of the piston valve cylinder correctly shows the piston at EXACT center with the driver turned apx. 3 degrees ahead of bottom center. One may have to think about that for awhile before it makes sense. And, yes, the bottom piston should should also have been shown at EXACT center. Oh, and by the way Wes, a short while back we were discussing the use of two firedoors on camelback locomotives. These Milwaukee Mallets also had two firedoors - I ran across this final photo this morning of one of these Milwaukee Mallets converted to oil - still with two firedoors! -Larry Doyle   Date: 09/24/18 09:22 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: wcamp1472 LarrryDoyle...

1. Can I presume that the two firedoors imply that there’s TWO oil burners? 2. I had forgotten about the possibility of using leaf springs in the balancer mode. What weight did the ‘lay shaft’ carry, when suspending the Stephenson reversing mechanism? W. Date: 09/24/18 15:53 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: LarryDoyle wcamp1472 Wrote:

------------------------------------------------------- > LarrryDoyle... > > 1. Can I presume that the two firedoors imply > that there’s TWO oil burners? Eight of the 36 engines were delivered as oil burners. The pic shows inspection holes in both firedoors, so I, too, presume there were two burners, though I only see one firing valve. I don't know if they only used one at a time and could switch to one or the other, or if they had a way to burn both at 1/2 capacity, or ???? Maybe there's another firing valve out of the picture to the left. West of Minneapolis Milwaukee burned about the 2nd poorest coal in the country (Only the NP's was worse that I know of). It was calculated that it would take 7,200 lbs. of coal to keep one of these saturated* kettles hot using Milwaukees' Roundup coal. The maximum a fireman could be expected to shovel was 5,000 lbs. per hour - that's continuously shoveling 11 scoops per minute. HARD WORK, but not enough So, Alco gave 'em two firedoors and Milwaukee provided two firemen 'till thhey were fitted with stokers or converted to oil. -LD *As saturated engines running compound the N1's would have had an exhaust pressure of somewhere around 8 psi. Which also reinforces the decision to give them two firemen. Not good for draft, and it earned them the nickname "slobberstacks". Date: 09/24/18 23:47 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: hawkinsun Boy, that sounds like a hell job trying to keep them stoked. It's hard to imagine two guys either bumping butts while shoveling, or dueling shovels if they were facing each other. Doing that for how many hours a day ? Wasn't it a sixteen hour rule back then ? And, that's long before Advil came out. Kill me now.

Craig Hanson Vay, Idaho Date: 09/25/18 06:11 Re: She's Quite A Beast To Send Up On A Branch Line Like This One Author: LarryDoyle The 16 hour law went into effect in 1918. N1's started arriving in 1910. Firemen were paid $4.15 per 100 miles (100 miles was considered a day) which was VERY GOOD pay considering most non-railroad jobs at that time paid about $1.00 a day.

Regarding shoveling, I can shovel three 10-15 lb. scoops every 15 seconds and still keep an eye on water, signals, gauges, and the track ahead, which works out to be well over 5,000 lbs of coal per hour. But I'm 75 and can't maintain that rate for more than 10 minutes or so without a break. -LD ------------------------------------------------------------------------------------------------------------------------------------------------------ OMG! There is a Power Reverse! While studying the builders photo posted above I found the reach rod from the reverse lever below the cab floor to the upper arm of the bell crank on the rear engine, thinking I had discovered there was no power reverse on these engines. But twp things about the picture did seem odd. First, the handle at the top of the reverse lever (the 'Johnson" bar) is not visible through the cab window, which it ususally is, and, second, there are two small cylinders or pistons along the edge of the ashpan, which I assumed to be some sort of grate shaker. I assumed the reverser handle had gotten painted out by the photographer in his studio. WRONG on both counts! In fact, I've discovered, there is a power revverse of unusual design. One of those two cylinders is an air operated piston attached to the Johnson bar. the other cylinder is an oil filled damper to supress feedback thorugh the reach rod! And, the reason the top of the bar is is not visible is that it was removable, mounted on thr reverse bar in the similare manner as a grate shaking bar. It was only installed by the engineer if the power reverser became inoperative. -John Stein aka Larry Doyle Edited 3 time(s). Last edit at 09/28/18 13:22 by LarryDoyle.  Date: 09/25/18 16:59 Re: OMG! There is a Power Reverse! Author: wcamp1472 LarryDoyle...

Never saw THAT! Happily these engines were scrapped before I was born.... How’d you like to RUN those beasts? W. Edited 1 time(s). Last edit at 09/25/18 23:19 by wcamp1472. |