| Home | Open Account | Help | 359 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

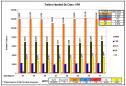

Eastern Railroad Discussion > Class 1 TOFC 8 Week MetricsDate: 08/11/20 04:46 Class 1 TOFC 8 Week Metrics Author: NSSpike The chart below shows the last 8 week numbers for trailers handled by five Class 1 railroads.

Inserted box lower right indicates week #31 2019. Not much change over the past 12 months. Inserted box top right 8 week average 2020. NOTE: Total is for ORIGINATED & RECEIVED The links below cover the some of the differences between TOFC COFC and the expanding refrigerated container market. https://transportgeography.org/?page_id=2575 https://www.joc.com/rail-intermodal/intermodal-shipping/us-railroads-nudging-shippers-away-trailers_20191010.html https://blog.intekfreight-logistics.com/refrigerated-intermodal-for-temp-control-shippers Thanks for stopping by and always be safe when out track side!!! Phil Maton Villa Rica, GA Edited 1 time(s). Last edit at 08/11/20 08:30 by NSSpike.  Date: 08/11/20 06:15 Re: Class 1 TOFC 8 Week Metrics Author: NSSpike In April 2017 the STB made several changes to the reporting metrics and began requiring Class 1's to include Car Loadings for 22 Commodity Groups. The table below indicates for a single week (#31) the Class 1 reported numbers for Trailers 2017 Vs 2020.

Phil Maton Villa Rica, GA Date: 08/11/20 07:56 Re: Class 1 TOFC 8 Week Metrics Author: NSSpike Back in the late 80's and early 90's NS ran a 21K off the KCS Dallas to Atlanta that was loaded with TOFC loads. Every east bound train would always have a healthy cut of LANCE trailers heading to or from Charlotte NC.

Phil Maton Villa Rica, GA  Date: 08/11/20 17:13 Re: Class 1 TOFC 8 Week Metrics Author: callum_out UP announced 20 plus years ago that they would no longer handle trailers, taking a while to go into effect.

The BNSF numbers are really interesting and show the impact of the UPS and Fedex and other trucking companies using rail. Out Edited 1 time(s). Last edit at 08/12/20 13:32 by callum_out. Date: 08/11/20 18:06 Re: Class 1 TOFC 8 Week Metrics Author: BRAtkinson 5+ years after retiring from CSX Intermodal, I'm convinced more and more that major shippers like UPS, are increasingly buying more trailers for intermodal service than containers. Even at a higher acquisition and shipping cost per unit, trailers have two major advantages over containers:

1. It has wheels and is ready to roll once it's on the ground. We sometimes had UPS drivers waiting for one of their loads to be grounded and would hook on as soon as the packer backed away from it. They'd give it a through roadability inspection and be out the gate as soon as possible. At the West Springfield, MA ramp, maybe 8-10 times per year we'd have a chassis shortage for a day or two or three which caused numerous delays to getting loads out of the yard and much angst among truckers as well as shippers. Unless otherwised directed to do so, we'd unload trains sequentially from one car to the next. I can remember multiple times where some loaded containers had to be put on the ground and waited more than 24 hours for a set of wheels! 2. Trailer maintenance and repairs are done by the owning company guaranteeing quality of work and materials. UPS, for example, likely has in-house mechanics at each of their larger ramps. Having equipment consistency across their fleet of trailers (and trucks) allows faster and more accurately performed repairs and they have full control over the parts used...particularly tires. I never paid much attention to whether UPS trailers had new or recap tires. But in the 7 years I was there, I never ONCE had one of their trailers come in with flat or damaged tires, nor any of them leave with bad tires. (Although I do recall getting called 2 or 3 times by UPS drivers on the way to the ramp that got a flat and were waiting for their company truck to come replace it) I firmly believe that UPS performs scheduled maintenance on all their fleet to ensure high availability and reliability. Compare that to the contract repair company at our ramp (I think most intermodal ramps contract out their chassis/trailer repair facilities) that while their workers did good work, they had the worlds' worst recap trailer tires to put on chassis (and trailers (if instructed by the trailer owning company), I think). I don't think there's any scheduled maintenance on pool chassis. It's strictly 'fix what's broken and go on to the next one'. I recall one of our better drivers, lost an hour or so to get one of the tires under a load he was picking up replaced. He got less than 2 miles from the ramp and that very tire blew out! Also, he was not alone with tires blowing out on hot days and heavy loads, or even the recaps flying off at normal highway speeds. Checking tires on everything that came in the gate, I saw recaps that the sidewalls were crumbling away but the tread was practically brand new! I wouldn't put a tire like that on my bicycle, much less under 20 tons of freight! As companies place more and more emphasis on service issues such as delivery times like UPS, reliability of fleet equipment is paramount. Reliable drivers and ramp staff is equally important to maintaining high levels of service. Date: 08/11/20 19:52 Re: Class 1 TOFC 8 Week Metrics Author: Drknow BRAtkinson: Every thing you say is anethma to PSR and UPRR INC especially maintenance, of anything; is not what supream leader EHH-blessings upon him- considerd neccisary. Hell UP doesn’t even have a shop open to do a class one on a Loco, you think they would take care of trailers? 😝 Just waiting for the house of card to fall.....

Posted from iPhone |