| Home | Open Account | Help | 347 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Model Railroading > Scratch building a turntableDate: 11/13/22 17:46 Scratch building a turntable Author: CNW I’m proto modeling the C&NW’s line through southern Minnesota, from Winona to Waseca in the 1976 era. The Waseca roundhouse burned in the early 1950s, but the turntable was in service in my era. To build the Waseca engine terminal, I needed a 95-foot half-through-plate-girder turntable. I like a good modeling challenge, so I decided to scratchbuild. I spent most of my spare time in September and October building the turntable. The first task was drafting CAD drawings of the prototype. The turntable is motorized using an HVAC damper motor. I repowered the damper motor with an Atlas can motor. The following is a photo documentary of the project.

-Dennis Photo 1: The pit walls were built using ½” cabinet plywood, sawing the round shapes with a jig saw with a fine tooth blade. Photo 2: TO puts videos after photos, so things are a bit out of order. This shows the pit wall after painting. The pit floor was made using light weight spackling. A donut shaped PC board was made and is mounted in the center of the pit. The PC board is used to get track power to the rails. Video 3: The pit wall has a layer of joint compound on it to simulate the concrete. I used the motor drive to make a rotary trowel to shape the joint compound. This process also helped keep everything concentric. Edited 1 time(s). Last edit at 11/13/22 17:58 by CNW.   You must be a registered subscriber to watch videos. Join Today! Date: 11/13/22 17:46 Re: Scratch building a turntable Author: CNW Photo 4: This shows the ½” plywood turntable core.

Photo 5: The four rollers at the corners of the table are dummies. Modified freight car trucks are mounted under the core and provide solid support on the circle rail. The flanges were removed from the wheels. Photo 6: Brushes on the bottom of the table contact the donut shaped PC board at the center of the pit to supply track power to the rails. A Digitrax AR-1 automatic reverser keeps the polarity aligned with the connecting tracks. Edited 1 time(s). Last edit at 11/13/22 17:49 by CNW.    Date: 11/13/22 17:46 Re: Scratch building a turntable Author: CNW Photo 7: The bridge structure and details were built from sheet styrene.

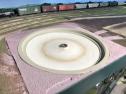

Photo 8: If I counted correctly, I applied 5,111 Archer rivets to the model. Photo 9: This shows the ties and deck boards being installed. Edited 1 time(s). Last edit at 11/13/22 17:52 by CNW.    Date: 11/13/22 17:46 Re: Scratch building a turntable Author: CNW Photos 10: The finished turntable. I used Envirotex to make the water in the turntable pit. The operator interface, a 3-position center off momentary toggle switch, is shown in the bottom left corner of the photo.

Photos 10 & 11: The finished turntable. Edited 2 time(s). Last edit at 11/13/22 18:26 by CNW.    Date: 11/13/22 18:00 Re: Scratch building a turntable Author: wabash2800 Dennis:

Thanks for sharing. That's great work as usual. It's nice to see rails in the pit, not like the Walthers turntable. And that's great that you used the decal rivets, something that I like doing on rolling stock and structures too. Perhaps some us would be interested in how the turntable is operated with the three position switch? And a video? Victor B/. Edited 2 time(s). Last edit at 11/13/22 18:02 by wabash2800. Date: 11/13/22 18:11 Re: Scratch building a turntable Author: TomG I'm speechless. Thats Master Model Railroader quality. I envy your skills.

Date: 11/13/22 18:21 Re: Scratch building a turntable Author: TomG I was caught up with the photos and didn't watch the video. Your rotary trowel is genius.

Date: 11/13/22 18:29 Re: Scratch building a turntable Author: DKay Work of art Dennis. Amazing work.

Regards,dK Date: 11/13/22 19:31 Re: Scratch building a turntable Author: atsf121 I am speechless, that is just flat out amazing modeling!

Nathan Date: 11/13/22 19:57 Re: Scratch building a turntable Author: icancmp193 A big WOW!

TJY Date: 11/13/22 19:58 Re: Scratch building a turntable Author: Frisco1522 Beautiful job! I've scratchbuilt a couple because nobody had the 100' length I needed. You did good.

Date: 11/13/22 22:27 Re: Scratch building a turntable Author: Coalca Dennis's work is the best of the very best.

Date: 11/14/22 05:01 Re: Scratch building a turntable Author: sp8192 As usual with your stuff...WOW! Incredible modeling! Over 5,000 rivots added individually is just craziness, but the finished product was worth it!

Date: 11/14/22 07:11 Re: Scratch building a turntable Author: CNW Thank you to everyone, for the complimentary comments!

sp8192 Wrote: ------------------------------------------------------- > Over 5,000 rivots added individually is just craziness, The rivets were actually applied in strips of 1-3 inches. Only a few were applied in groups of two, but yes still crazy. Dennis Edited 1 time(s). Last edit at 11/14/22 08:35 by CNW. Date: 11/14/22 19:37 Re: Scratch building a turntable Author: kingwestinghouse That is KILLER. Nice work

Posted from iPhone |