| Home | Open Account | Help | 389 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Model Railroading > BNSF 72’ Frostline Reefer (Part 14) – Kling-OnsDate: 11/29/22 00:00 BNSF 72’ Frostline Reefer (Part 14) – Kling-Ons Author: tmotor This is Part 14 of a series on the BNSF 72’ Frostline Reefer project. (Parts 1 thru 13 were posted earlier.)

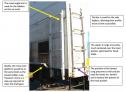

Just Around the Corner On the B-end, there are 4 ladders that wrap the corners. As usual, they are mounted with the rungs lined-up, to make the transition around the corner as predictable as possible for crews. The ladders on the end of the car have the usual brackets to bring it away from the car to provide clearance for boots and hands. Wide Load The ladders on the car sides are a different story. In order to maximize the thickness of the insulation, the sides are pushed out to the limit of a Plate F Clearance. When it comes to attaching the ladders to the sides, the usual angle iron would bring the ladders too far away from the car, and foul the Plate F restrictions. Instead, flat bar was used to support the ladder rungs. In order to still provide safe footings, there are rectangular pockets at each rung. This provides the clearance needed for boots and hands, while maximizing the insulation. Toe Hold The pocket will only allow enough room for the boot to land on the ball of the crew member’s foot. This is fine for temporary movements, such as getting onto the cross-over platform. However, if the crew member plans to hitch a ride for several miles to the next siding, it would be more comfortable to use the stirrups (below the ladder). Stirrups do not limit boot movement, allowing the stirrup rung to land on the foot arch. This is a much more comfortable position for clinging to the ladder for a ride lasting more than a few minutes. Edited 3 time(s). Last edit at 11/29/22 00:15 by tmotor.   Date: 11/29/22 00:00 Re: BNSF 72’ Frostline Reefer (Part 14) – Kling-Ons Author: tmotor Can’t Touch This

For some reason, the brake wheel gearbox is NOT mounted to the end sheets. Instead, a long back plane was fabricated as the mount. It begins at the underframe, then runs vertically for a few feet, parallel to the end sheets which are just inches away. The only attachment point for the back plane is the underframe. This appears to be intentional, as it is a lot more work than the usual simple square bracket attached to the end sheets. Perhaps the end sheets were too thin to withstand the tension of the chain when the brakes are set. It is also possible the goal was to have a thermal break, so the gearbox and brake wheel wouldn’t act as heat sinks. Dave Edited 1 time(s). Last edit at 11/29/22 00:02 by tmotor.    Date: 11/30/22 09:06 Re: BNSF 72’ Frostline Reefer (Part 14) – Kling-Ons Author: ChrisCampi I get the impression that the car was designed to have as few body mounts as possible, maybe to uncomplicate the insulation fabrication? It's been pretty amazing following you series, how a simple cube of a car ,is really anything but.

Date: 11/30/22 17:08 Re: BNSF 72’ Frostline Reefer (Part 14) – Kling-Ons Author: tmotor Season's Greetings, Chris!

> I get the impression that the car was designed to have as few body mounts as possible, maybe to uncomplicate the insulation fabrication? Agreed. Trinity was pushing the envelope with the plastic roof, so it appears the insulation was made a priority. > It's been pretty amazing following your series, how a simple cube of a car ,is really anything but. Indeed! There is definitely more than what appears at first glance. It is refreshing to be on this side of the CAD geometry. Instead of merely identifying some feature in a model that wasn't included, I have the opportunity to add it and make it prototypical. However, this reverse-engineering process is taking longer than I anticipated. CAD starts with a clean slate, so lots of dimensions are needed. Consequently, I've examined just about every square inch of an entire Frostline Reefer, from as many angles as possible. It is easy to make a career of just one component; such as a Plug Door. Occasionally I will realize a better approach to a piece of geometry, and start over using what I learned from the first attempt. It is nice to have the luxury of time, and NOT get stressed about meeting a deadline. :-D Take care and God bless! Dave Edited 1 time(s). Last edit at 12/03/22 14:03 by tmotor. Date: 11/30/22 18:02 Re: BNSF 72’ Frostline Reefer (Part 14) – Kling-Ons Author: ghemr Based on your attention to detail I think you'd be a perfect candidate for a model railroad manufacturer's team!

Date: 12/01/22 14:49 Re: BNSF 72’ Frostline Reefer (Part 14) – Kling-Ons Author: tmotor Season"s Greetings, ghemr!

> Based on your attention to detail I think you'd be a perfect candidate for a model railroad manufacturer's team! I appreciate the kind words. :-D This pursuit of details to reverse-engineer an entire Frostline Reefer is definitely a labor of love. It has been on my radar for decades. My first set of documentation was assuming a kitbash. Most of the measurements are already done by the manufacturer. With the introduction of CAD and 3D printing, I had to up my game. Fortunately the Frostline Reefers are still around for me to further document. I'm glad folks are Viewing this series of posts. Frankly, I was wondering if this level of detail would be considered TMI, but there are consistently 400+ Views. BTW, I use the Views to determine the level of interest (vs. reply posts). As long as folks find it interesting and View them, I will keep posting. ;-) Take care and God bless! Dave Date: 12/01/22 22:16 Re: BNSF 72’ Frostline Reefer (Part 14) – Kling-Ons Author: atsf121 ChrisCampi Wrote:

------------------------------------------------------- > ... how a simple cube of a car, is really anything but. So true! |