| Home | Open Account | Help | 313 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Steam & Excursion > Belpaire fireboxesDate: 10/07/13 08:00 Belpaire fireboxes Author: sarailfan Watching the video of the K4s below reminded me of Pennsy's love for the Belpaire firebox. What were the advantages of the Belpaire versus a "standard" firebox. I'm mostly familiar with CPR steam, with a touch of GN (being from western Canada and all), and know that some of their early steam used a wagon-top boiler to get additional water over the crown sheet. Was the Belpaire also designed for this purpose? Seems to me it would be a difficult job to adequately stay those top, and especially front, corners of the firebox as pressures increased.

Thoughts? Darren Boes Lethbridge, AB Southern Alberta Railfan Date: 10/07/13 08:15 Re: Belpaire fireboxes Author: HotWater Probably the biggest advantage was reduced stresses on the stay bolts, since virtually all where the same length, especially in the crown sheet area. In a radial stayed firebox the flexible crown bolts are varying lengths and may also be "side loaded/stressed" due to the radial design.

Date: 10/07/13 11:45 Re: Belpaire fireboxes Author: LarryDoyle sarailfan Wrote:

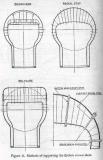

------------------------------------------------------- > Watching the video of the K4s below reminded me of > Pennsy's love for the Belpaire firebox. What were > the advantages of the Belpaire versus a "standard" > firebox. I'm mostly familiar with CPR steam, with > a touch of GN (being from western Canada and all), > and know that some of their early steam used a > wagon-top boiler to get additional water over the > crown sheet. The wagon top boiler did not provide space for extra water, but rather for steam space and to allow the throttle to be located further above the waterline. Because of the rapid changes in steam demand made of a locomotive boiler, the steam space is needed to serve as a cushion when opening the throttle to reduce priming and lifting of water into the throttle. Next to the PRR, the GN was North Americas largest user of Belpaire fireboxes, right up to the end of steam, but many other railroads made use of the design in the 1890-1910 era. (Casey Jones' engine had a Belpaire firebox.) > Was the Belpaire also designed for > this purpose? Seems to me it would be a difficult > job to adequately stay those top, and especially > front, corners of the firebox as pressures > increased. The idea was to allow staybolts to be placed as perpendicular as possible to the inside firebox sheet and outside wrapper, which minimized flexing of the staybolts which is a problem with radial stayed fireboxes. These drawings illustrate the difference in how staybolts are arrayed. Also shown is how flexible staybolts are used, and the very old style (pre 1900) crown bar firebox. Bracing the corner is not a factor on any firebox design, as tightly curved surfaces are naturally stronger than surfaces that are flat or of long radius. -John Edited 3 time(s). Last edit at 10/07/13 14:51 by LarryDoyle.  Date: 10/07/13 13:59 Re: Belpaire fireboxes Author: wcamp1472 I'm speculating here.....

If I recall correctly, the PRR's Belpaire firebox outer wrapper sheets were the same thickness as the internal firebox sheets, i.e.: 3/8 inches. A typical RADIALLY stayed firebox has the outside, 'wrapper sheet' of stouter material --typically 1", or better. Since the Belpaire is all "right-angle" braced, the pressure-related stresses are better 'handled' by the stronger, and probably larger, stays than the radial stayed fireboxes. As stated, above, the 'corners' are a self-rigid-ized construction. The 'straight-lines' of the supporting stays are materially stronger (because they can be more closely spaced than comparable radial-stayed boilers). The Radial stays are more widely-spaced at the outer-ends of their lengths -- requiring a 'stouter' wrapper sheet construction -- necessitated by the greater 'un-stayed' areas that are inherent in the Radial designs (as illustrated, above). For PRR, the greater Cost-Benefits (even $Million$ of dollars, back in those days) of the Belpaire were significant--- especially since there were, virtually, 1,000 boilers rolled for the K4 and L1 classes (combined). At 205 PSI, and a safety factor of four, that gives you a theoretical design safety factor of 820 PSI: 4x205= 820 PSI 'design' pressure; well within safe boiler construction practice*. The PRR had MANY Belpaire firebox locos. I suspect that recent 'challenges' with the integrity of the K4s, 1361's, restoration may be related to the possible 'wastage' (rusted/erosion) condition of the top sheets and the outside wrapper side sheets. If the eroded, 3/8" thick, original wrapper sheets were materially 'thinner' than the design specs, the firebox & boiler pressures would have had to be severely de-rated (reduced pressures)...in order to maintain the 4:1 safety factor required. That may be the 'rest of the story' about the recent decision to halt work on that fine loco. [It is also an "area of concern" to 'qualify' the other extant PRR locos (with Belpaires) to see, and measure, the possible deterioration of their Belpaire firebox roof and wrapper sheets -- especially if they spent any time exposed to the seasonal elements and weathering. There is very little room for error if the PRR's thin outer-wrapper sheets are severely eroded]. (* Note: That Safety Factor of Four, is deceptive: That works if all the boiler parts, exposed to the direct effects of the fire's flames, are submerged in the much colder boiling water. Unfortunately, with most common dropped-crown sheets and violent boiler explosions, the crown has had large areas go 'dry' (no cooling water), resulting in massive destruction and deaths. Steam, in the boiler's dry & exposed areas does NOT have any cooling effects for the over heated steel --the staybolt holes get softer and stretch, tending to drop off the ends of the supporting stays -- resulting in dropped crowns and suddenly-lowered boiler pressures. If you suddenly lower the pressure on 500 deg F. water, what happens to all that water? It ALL FLASHES SUDDENLY into explosive steam! Ask Evil Knievel about his steam-powered motor-cycle jump across that river in the state of Washington -- he NEVER jumped any bike again! Steel softens as it gets hotter. In fact, steel, if viewed in a dark room, is heated to a barely-visible dark red incandescent heat --- it becomes EIGHT Times more weak, than at the cooler temperatures of the hot water in the boiler. SO, if the boiler has a design safety factor of 4, but hot steel softens by a factor of EIGHT, then you no longer have any safety factor. Read the NTSB report of the boiler explosion of the ex-CP 1278 on the Gettysburg RR in the 1990s --- it should scare you to death!) (Send me a private message if you want the info for the NTSB's on-line report..) Wes. Date: 10/08/13 14:02 Re: Belpaire fireboxes Author: challenging_grades If I remember correctly, the problem with the current Belpaire fireboxes is not due to wastage. I believe the crown and roof sheet were originally 3/8" and both have a slight radius. This means that the crown sheet will have a smaller staybolt pitch (center line to center line of the bolts) than the roof sheet we the bolts will be diverging as they head to the roof sheet. (Basically the bolts are in line with the radius of the curves which means they are normal to the sheets).

To compensate for the larger pitch on the roof sheet, the Pennsy had the bolts stick through the roof sheet and applied a large nut to the end of the bolt to increase its holding power. This put the safety factor in spec with code. However during their career, Pennsy removed the nuts and from what I have seen, it appears that they did not re do the calculations as by removing the nuts, the safety of factor is less that what the code calls for. So while it worked as the rupture pressure was still greater than operating pressure, the safety factor was less that what is should have been. |