| Home | Open Account | Help | 315 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

Steam & Excursion > Whazzit? (46)Date: 04/08/21 14:50 Whazzit? (46) Author: LarryDoyle A slash bar. (As in, on a steam locomotive, not in a horror movie.)

What is it? What is it used for? By whom? Why? Where would you find one if you needed it? Could it be misused? How? What happens if it is misused? LD Date: 04/08/21 15:44 Re: Whazzit? (46) Author: wcamp1472 Slash bar..

I know what it is, but I've never had to use one. I'd be interested in the responces.. W.. Date: 04/08/21 16:31 Re: Whazzit? (46) Author: HotWater I've had to use one, on 4449, a number of times. Depending on the quality of the fuel oil, a carbon "hump" can sometimes build up about 2 or 3 feet off the burner. As the "bone", as the old-timers called it, increases in size, it will tend to deflect the flame off the burner, and affect firing performance. When there is a stop of some length, the slash bar is retrieved off the tender deck, and passed down through the cab roof access to to top of the tender/oil bunk. With the firedoor open, the slash bar is passed downward and through the firedoor, and the carbon "bone" is quickly broken up, with the pieces of carbonized oil distributed around the floor of the firepan. All this must be done fairly quickly, as the slash bar gets VERY hot, even though the fire is out, and welding gloves are used to handle the long bar. The hot slash bar is re-stowed back on top of the oil bunk, the firedoor is closed, and the fire re-lit with a fusee.

In an engine servicing terminal, a Hosteler Helper would also perform this operation. Date: 04/08/21 20:58 Re: Whazzit? (46) Author: MojaveBill One of the reasons we have diesels...

Bill Deaver Tehachapi, CA Date: 04/09/21 06:19 Re: Whazzit? (46) Author: LarryDoyle Interesting, Jack. I've not heard of ever needing a slash bar on an oil burner before. Standard equipment? Is that carbon buildup from overfiring? A malfunctioning burner? Insufficient oxygen?

Nor, of using the cab roof hatch for getting tools from the tender deck into the cab. But, I suppose with an all weather cab ..... -LD Date: 04/09/21 06:28 Re: Whazzit? (46) Author: train1275 MojaveBill Wrote:

------------------------------------------------------- > One of the reasons we have diesels... Well maybe, but right now I'm trying to get EMDEC to talk to FIRE and the CHMM and LIG and figure a possible screen issue while installing PTC and interfacing Ultra Cab II, and I'm ready to get a slash bar and really fix the mess. A Nickel Plate Berk or an SP GS Class looks pretty good right now. Posted from Android Edited 1 time(s). Last edit at 04/09/21 06:29 by train1275. Date: 04/09/21 06:52 Re: Whazzit? (46) Author: Frisco1522 Jack described it well. I've never understood exactly why the carbon forms like that. Some days you can run all day without the lump and others it looks like the Statue of Liberty on the floor.

That's when you go to work with the slash bar, plus try to break it up into smaller pieces while you're at it. And yes, the bar DOES get hot! Date: 04/09/21 07:35 Re: Whazzit? (46) Author: LarryDoyle OK, Frisco, you broke it up. Then what do you do with it? Take it out in pieces thru the fire door? Push it out thru the air damper? Break it into small enough pieces that it will blow out the stack? Ignore it and leave it for the next guy?

-LD Date: 04/09/21 08:01 Re: Whazzit? (46) Author: HotWater LarryDoyle Wrote:

------------------------------------------------------- > OK, Frisco, you broke it up. Then what do you do > with it? Take it out in pieces thru the fire > door? Push it out thru the air damper? Break it > into small enough pieces that it will blow out the > stack? Ignore it and leave it for the next guy? > > -LD In most cases, simply "breaking up the bone", and spreading the pieces around the floor of the firepan was sufficient. Over time, the pieces just seemed to burn-up in the hot fire when working. I remember, one case with 4449, where the bone was big enough that even breaking it down with the slash bar, still left a thick lump on the firepan floor. The next time the locomotive was shut down for a number of days (maybe a boiler wash), we went into the firebox with a pick-ax and chopped up the hardened mess, put it in buckets, and dragged it out the fire door. I can not remember ever having to drag large pieces out the firedoor. Simply spreading them around the floor of the firepan always seemed to burn them up. Date: 04/09/21 14:58 Re: Whazzit? (46) Author: LarryDoyle In Whazzit? (45) we discussed clinker, and cleaning the fire: https://www.trainorders.com/discussion/read.php?10,5227593,5229500#msg-5229500

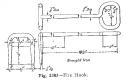

What Jack describes above sounds like it must be the oil burning equivalent of a clinker in a coal fire. Fig. 2384, below, from the 1906 Locomotive Dictionary would appear to be a tool for dealing with that mess in an oil burning firebox. I've never seen a real life tool such as this one, nor that "Statue of Liberty" experience! Fig. 2383, therein is called a Fire Hook but also is called a slash bar or a rake. I've heard these terms used interchangably. Many of these these have only one tine on the "hot" end. Also pictured are a pair of awesome, near 20 foot long, firehooks for DM&IR 2-8-8-4's! There is a third member of this family of the firemans tools, the hoe shown in Fig. 2369, the fourth illustration from the 1922 Locomotive Cyclopedia. So, if you're firing coal, how do you know when you need one or these tools? Where would you find one? And what would you do with it? -LD Edited 3 time(s). Last edit at 04/12/21 13:30 by LarryDoyle.    Date: 04/09/21 15:01 Re: Whazzit? (46) Author: LarryDoyle Date: 04/09/21 15:08 Re: Whazzit? (46) Author: HotWater Nice drawing of a "fire hoe". The "slash bar" used on SP oil burning locomotives (and probably Santa Fe locomotives also) was similar, except that plate welded at the end would NOT have been at 90 degrees to the bar stock shaft. The SP "slash bar" was pretty thick round bar stock (at least 1" in diameter", and that pieces of steel plate was NOT welded at 90 degrees to the bar stock (it was welded straight on in order to dig/break-up the carbon bone).

Date: 04/09/21 17:19 Re: Whazzit? (46) Author: Frisco1522 LarryDoyle Wrote:

------------------------------------------------------- > OK, Frisco, you broke it up. Then what do you do > with it? Take it out in pieces thru the fire > door? Push it out thru the air damper? Break it > into small enough pieces that it will blow out the > stack? Ignore it and leave it for the next guy? > > -LD Yes Date: 04/09/21 21:51 Re: Whazzit? (46) Author: LarryDoyle So, where do you keep that slash ber when you're not using it?

Jack's method of keeping it on top of the tender of an oil burner can only work when you only use it when the engine is stopped. But coal fired engines require more attention, up close and personal, while running down the track. And, it's too big to fit under the firemans seat box. One place to look for 'em would be hung on hooks horizontally above the doorway of the back cab wall. Another is on the front wall of the tender, above the boards or doors which separate the coal space from the gangway. But those spaces only can handle bars up to about 8 feet long. Most fireboxes require much longer bars than that. The common solution is something you probably never knew about being on a tender. A tube about 8 inches is diameter is often built into the tender, passing thru the coal space from the front of the tender and into the tenders water space! The length of the tube is about 10 inches less than the length of the bar, so the bar won't slide in and be difficult to get out next time you need it. After using the tool the fireman draws it back from the fire door and slides into the tube for storage. And, yes it is HOT. HOT. Like glowing cherry red hot. DO NOT TOUCH THE HOT END OF IT! -LD Edited 1 time(s). Last edit at 04/09/21 21:58 by LarryDoyle. Date: 04/10/21 02:43 Re: Whazzit? (46) Author: wcamp1472 What's the best "grip" to use when using the long, 2-prong

fire hook, as in the photo ( above) of two of them? The Reading T-1s have a "hook storage tube" in the tenders, firemans' side.. For safety, you could easily slide the hot hook directly into the tube, with a quick, knee-high, lateral toss....avoiding the hot, glowing ends T-1s sometimes operated under electrified catenary in the Philadelphia commuter territory.... Lou Cook, of Jersey Shore Commuter's Club, tells of a crew getting into the cab of a PRR K4, at South Amboy service tracks, and finding a long handled fire hook 'welded' to the fire doors of the engine's backhead....with the long handle sticking out beyond the cab roof. The fresh crew was confronted with a mystery, since no one owned up to the 'event'. Areas of South Amboy yards are under 11,000 volt Catenary. W. Edited 2 time(s). Last edit at 04/12/21 08:35 by wcamp1472. Date: 04/10/21 08:32 Re: Whazzit? (46) Author: LarryDoyle LarryDoyle Wrote:

------------------------------------------------------- > Could it be misused? How? What happens if it > is misused? > > LD Nobody touched this part of the questions in the original post. The answer is a definite "Yes. Easily misued." Its misuse can be very damaging to the engine. Though a useful tool for cleaning a fire at the start of the day, and such, it should not be used on the road if at all pssible. A greenhorn fireman quickly discovers that if he's having a hard time keeping up with the fire and is loosing pressure he can quickly raise the firebox temperature and raise steam by raking the firebed with the slash bar. This lets in lots of oxygen and the fire gets hot fast. But the rapid temperature change is bery abusive to the boiler. You will hear it complain as it lets our creaking, popping, and even loud banging sounds. This is not good. It also raises ash from the bottom of the fire onto the top where it melts and forms clinker, makiing his problems worse. Misuse and abuse will cause leaking flues and staybolts, and even breakage of staybolts. Good firing technique will not damage the boiler, and in fact properly fired an engine will often self heal leaks at flues and staybolts. -LD Date: 04/10/21 10:34 Re: Whazzit? (46) Author: wcamp1472 Not about the 'slash bar'...

A different 'take' on the use of the long 'hook' or 'rake'.... I was taught by RDG General Boiler Inspector, as well as experienced NKP firemen about managing the firebed. But first, I'll explain the reference about the 'proper grip' to be used when working with the 'hook' inside the firebox. One use is the maneuvering of solidified, glass-like large amalgamations, commonly called 'clinkers'. Often mis-identified as 'clinkers' , there are mounds of uninvolved, non- burning mounds of green coal, more pripoerly called banks of coal. They are two separate accumulations. The mounds of coal, if needed can be pushed around and spread out, and will soon be 'fully involved'. Clinkers are a solid cooling-off mass that no air passes through. Most clinkers originate from novice firemen raking around in the fire mixing the ash layer of the fire bed up into the active burning layer ---- a very stupid practice. The ash, when reheated and mixed in the burning region, will have the "silica unburables" begin to melt and fuse together ... Thus, the novice has inadvertently created the beginnings of forming a clinker...The clinker grows around its edges, and soon dams-off large areas of the grate from free oxygen flow paths. So, the experienced NKP master-firemen would only use the 'hook' to physically move clinkers or pieces of clinkers into the rear corners of the grate. It's best to flip the clinker over, like a turtle on its back, then cover the entire corner, clinker and all in fresh green coal --- several feet thick. After about half an hour, while pulling freight, the coal, clinker and all will burn down-- nice and level with the rest of the firebed. Primary use of the hook by the NKP crews was in clinker management. Some coals, with high silica content will form clinkers as part of the combustion process, without any prompting from improper use of the rake. With self-clinkering coal, use of the rake to move the clinkers into the rear corners is wise use. The second use of the rake is at the end of the run fire-cleaning time. Grates constructed with "rocking fingers", continuously rattle and shake while underway---sifting dead ashes into the ash pan. The shaking enhances the loose particles out if tge bed to become airborne and they flow up the stack with the fly ash formed by fine coal burning in mid-air on the way through the flues and tubes... With heavy freights, and strong, steady drafts the "finger grates" make the firebed a continuously self-cleaning process that cuts down down on the ash build-up on the grates. You often would burn 20-tons of coal, and the 700s arrive at the treminal ash pit...."only dumping a wheelbarrow full of ashes" .....as Al Phillips used to say. So, at the pit was where the decision to dump the firebed, or just clean it. If Dumping, you use the rake to manage getting all the 'bones' of the fire through the grates and into the ash pan. if just cleaning the fire, you want to preserve the live, burning coals, and sift-out the ash. So, gentle rocking of tge grates will suffice. The remaining burning coal will go out soon, so you want to run the stoker to completely cover the grate in green coal ... after about 30 minutes, you will have a completely cleaned and recovered fire. Add in a heavy bank across the rear of the grates, and you're ready for the 'road'. If you've had to wrestle clinkers, all you need to do is get them to the rear corners, and bury them in green coal to become part of your 'rear bank'... You can regulate the size of the bank's coverage area of the grates, to suit the anticipated train mass to be hauled from 30 or so cars to 100 cars of freight .... A heavier train means a larger grate are will ne needed, a light train, means a heavier, more expansive bank. It's purpose is to dam off the unused grate area and to prevent cold air from damaging the rear sheets and lower rear corners. The rear bank is allowed to become a glowing, coked mass..and you periodically add more green coal to become more fuel for the coke-bed. ALSO, sometimes after you've let the thin, forward section of fire burn itself out, you can use the long rake to break up the coked bank, roll chunks forward and run the stoker add fresh coal onto the broken-up coke & to recover a 100% full fire.. I prefer to build a fresh fire on top of an existing, cold, ash bed. With a "young fire", the existing , cold, ash bed acts to dam-off the free flow of cold air through the firebox and boiler. Once we're ready, I may give the grates a quick, gentle rocking to sift the deeper ash build-ups into the ash pan. if scheduled work is to be done in the firebox, then completely dumping the ashes and washing the grates makes the workspace neater. Now, back to the 'proper grip' when using the rake: The proper grip of the rake's loop handle has you grasping the rake where the loop,' inside' where the loop of the handle begins. You place you hand up, through the center of the loop, and put two fingers on either side of the shaft, ( at the 90- degree bend) and curled around the handle's inner loop. You then have the back portion of the loop protecting the back of your hand.. Sometimes when wrestling clinkers and heavy masses, the clinker will suddenly break, and your arm & rake will jump back as you're pulling really hard!! Now protected, when your hand & rake slams into the cab's steel walls, you'll hear a loud BANG! But you dont have broken bones in your hand!!!! That's how a Professional handles that loop in the handle --- the rake/hook is NOT a shovel... DO NOT grab it, like it is a shovel !! In the cab, live-demonstrations when I was describing the use of the rake/ hook, I'd have my hand inside the loop, & be discussing and demonstrating pulling really hard --- then I'd SMACK the rear cab wall with the exposed back loop. ( as if a stubborn clinker suddenly broke apart) --- with a really LOUD, solid and fast SLAM into the cab rear wall --- everybody would gasp and jump with imagined pain of my hand --- I'd smile and wiggle my fingers, safe inside the loop.. They'd all laugh, relax and breathe deeply, as they realized that all was safe .. and that I was not hurt. Everyone of them learned that very simple lesson.. first shown to me at Conneaut, by friendly NKP crews. and the 759....way back in the "Summer of '69". ( with apologies to Bryan Adams...) Wes Camp ( OOPS .. I FORGOT THE MOST IMPOSTRANT SAFETY PRACTICE: ALWAYS WEAR STURDY WORKERS' GLOVES WHEN HANDLING THE HOOK / RAKE..!!! ) Edited 9 time(s). Last edit at 04/11/21 09:53 by wcamp1472. Date: 04/11/21 07:55 Re: Whazzit? (46) Author: ChrisCampi Very interesting thread.

Date: 04/12/21 12:23 Re: Whazzit? (46) Author: Arved In photos, I've seen the tool on tender decks of (some?) Southern Pacific locomotives. Not knowing any better, I thought they were to hook the water fill over, and pull it over the fill hatch. Now I know better!

Thanks! Arved Grass Fleming Island, FL Date: 04/12/21 12:27 Re: Whazzit? (46) Author: HotWater Arved Wrote:

------------------------------------------------------- > In photos, I've seen the tool on tender decks of > (some?) Southern Pacific locomotives. Not knowing > any better, I thought they were to hook the water > fill over, and pull it over the fill hatch. Now I > know better! > > Thanks! Well, you are still correct, as most of the large SP steam locomotives also had one of those "light weight" water spout/oil spout "hooks", carried in top of the oil bunk. Made out of much smaller diameter round steel stock, so that it was much lighter and much shorter than the big slash bar. |